ISSN 1004-5759 CN 62-1105/S

草业学报 ›› 2023, Vol. 32 ›› Issue (8): 164-175.DOI: 10.11686/cyxb2022384

• 研究论文 • 上一篇

赵杰1( ), 尹雪敬1, 王思然1, 董志浩1, 李君风1, 贾玉山2,3, 邵涛1(

), 尹雪敬1, 王思然1, 董志浩1, 李君风1, 贾玉山2,3, 邵涛1( )

)

收稿日期:2022-09-27

修回日期:2022-12-05

出版日期:2023-08-20

发布日期:2023-06-16

通讯作者:

邵涛

作者简介:E-mail: taoshaolan@163.com基金资助:

Jie ZHAO1( ), Xue-jing YIN1, Si-ran WANG1, Zhi-hao DONG1, Jun-feng LI1, Yu-shan JIA2,3, Tao SHAO1(

), Xue-jing YIN1, Si-ran WANG1, Zhi-hao DONG1, Jun-feng LI1, Yu-shan JIA2,3, Tao SHAO1( )

)

Received:2022-09-27

Revised:2022-12-05

Online:2023-08-20

Published:2023-06-16

Contact:

Tao SHAO

摘要:

为评价贮藏时间对甜高粱青贮发酵品质、微生物群落组成和功能的影响,将蜡熟期甜高粱(SS)自然青贮1、3、7、15、30和60 d,开窖后,随机取样进行化学成分、发酵参数和微生物数量分析。同时,对鲜样、青贮7和60 d的甜高粱青贮饲料(SSS)进一步进行高通量测序和KEGG功能预测分析。结果表明,青贮60 d后,甜高粱青贮饲料呈低pH值、高乳酸含量和高乳乙比的同型乳酸发酵。肠杆菌属(26.0%)和泛菌属(25.7%)为SS鲜样的优势菌属,而明串珠菌属(34.1%)和乳球菌属(31.6%)则在7 d的SSS中占据优势,随后在60 d的SSS中被乳杆菌属(73.5%)取代。斯皮尔曼相关性热图显示乳杆菌属相对丰度与乳酸含量呈正相关,与pH值呈负相关。青贮前后微生物群落功能存在较大差异:青贮过程下调了氨基酸、能量、辅因子和维生素代谢,但上调了核苷酸和碳水化合物代谢。总体而言,高通量测序结合KEGG功能预测分析进一步证实了甜高粱青贮过程中球状乳酸菌至杆状乳酸菌的演替规律,并初步发现了碳水化合物代谢上调及氨基酸代谢下调的功能转变趋势。研究青贮过程中的微生物群落动态和功能变化对深入揭示厌氧发酵机理和生产高品质青贮饲料具有重要意义。

赵杰, 尹雪敬, 王思然, 董志浩, 李君风, 贾玉山, 邵涛. 贮藏时间对甜高粱青贮发酵品质、微生物群落组成和功能的影响[J]. 草业学报, 2023, 32(8): 164-175.

Jie ZHAO, Xue-jing YIN, Si-ran WANG, Zhi-hao DONG, Jun-feng LI, Yu-shan JIA, Tao SHAO. Effects of storage time on the fermentation quality, bacterial community composition, and functional profile of sweet sorghum silage[J]. Acta Prataculturae Sinica, 2023, 32(8): 164-175.

| 项目Item | 含量Content |

|---|---|

| pH | 5.23±0.04 |

| 干物质Dry matter (%鲜重Fresh weight) | 31.90±1.08 |

| 水溶性碳水化合物Water-soluble carbohydrates (%DM) | 28.40±0.41 |

| 粗蛋白Crude protein (%DM) | 5.13±0.61 |

| 缓冲能Buffering capacity (mEq | 50.90±6.05 |

| 中性洗涤纤维Neutral detergent fiber (%DM) | 55.30±0.29 |

| 酸性洗涤纤维Acid detergent fiber (%DM) | 29.50±0.15 |

| 乳酸菌Lactic acid bacteria (lg CFU | 8.59±0.06 |

| 好氧性细菌Aerobic bacteria (lg CFU | 8.57±0.04 |

| 酵母菌Yeasts (lg CFU | 7.86±0.03 |

| 霉菌Molds (lg CFU | 6.00±0.14 |

| 肠杆菌Enterobacteria (lg CFU | 8.67±0.10 |

表1 甜高粱鲜样的化学成分和微生物组成

Table 1 The chemical and microbial composition of fresh sweet sorghum (means±standard deviations)

| 项目Item | 含量Content |

|---|---|

| pH | 5.23±0.04 |

| 干物质Dry matter (%鲜重Fresh weight) | 31.90±1.08 |

| 水溶性碳水化合物Water-soluble carbohydrates (%DM) | 28.40±0.41 |

| 粗蛋白Crude protein (%DM) | 5.13±0.61 |

| 缓冲能Buffering capacity (mEq | 50.90±6.05 |

| 中性洗涤纤维Neutral detergent fiber (%DM) | 55.30±0.29 |

| 酸性洗涤纤维Acid detergent fiber (%DM) | 29.50±0.15 |

| 乳酸菌Lactic acid bacteria (lg CFU | 8.59±0.06 |

| 好氧性细菌Aerobic bacteria (lg CFU | 8.57±0.04 |

| 酵母菌Yeasts (lg CFU | 7.86±0.03 |

| 霉菌Molds (lg CFU | 6.00±0.14 |

| 肠杆菌Enterobacteria (lg CFU | 8.67±0.10 |

项目 Item | 贮藏时间Ensiling time (d) | SEM | P值 P-value | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 7 | 15 | 30 | 60 | |||

| pH | 4.47A | 3.95B | 3.76C | 3.70CD | 3.61D | 3.59D | 0.072 | <0.001 |

| 乳酸Lactic acid (LA, %DM) | 0.64A | 4.29A | 5.80A | 7.85A | 12.40A | 13.20A | 1.887 | 0.438 |

| 乙酸Acetic acid (AA, %DM) | 0.15C | 0.78BC | 1.13BC | 1.90ABC | 2.34AB | 3.19A | 0.276 | 0.002 |

| 乳乙比LA/AA | 4.45A | 5.76A | 5.43A | 4.13A | 3.17A | 4.13A | 0.449 | 0.518 |

| 丙酸Propionic acid (%DM) | 0.04BC | 0.02BC | 0.00C | 0.03BC | 0.06B | 0.11A | 0.009 | <0.001 |

| 正丁酸n-butyric acid (n-BA, %DM) | ND | ND | ND | ND | ND | ND | - | - |

| 异丁酸Isobutyric acid (IBA, %DM) | ND | ND | ND | ND | ND | ND | - | - |

| 挥发性脂肪酸Volatile fatty acid (VFA, %DM) | 0.19C | 0.79BC | 1.14BC | 1.93ABC | 2.40AB | 3.30A | 0.173 | 0.002 |

| 乙醇Ethanol (%DM) | 0.09B | 0.04B | 0.08B | 0.16AB | 0.23AB | 0.33A | 0.027 | 0.002 |

| 1,2-丙二醇1,2-propanediol (%DM) | ND | ND | ND | ND | ND | ND | - | - |

| 干物质Dry matter (%FW) | 32.3A | 31.1AB | 29.6B | 29.5B | 29.1B | 29.5B | 0.315 | 0.006 |

| 水溶性碳水化合物WSC (%DM) | 28.2A | 25.1A | 25.2A | 19.2B | 18.2BC | 14.4C | 1.174 | <0.001 |

| 氨态氮Ammonia nitrogen (NH3-N, %TN) | 6.48A | 7.68A | 7.75A | 7.68A | 8.01A | 8.51A | 0.230 | 0.245 |

表2 贮藏时间对甜高粱青贮饲料化学成分和发酵品质的影响

Table 2 Effects of storage time on the chemical composition and fermentation quality of sweet sorghum silage

项目 Item | 贮藏时间Ensiling time (d) | SEM | P值 P-value | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 7 | 15 | 30 | 60 | |||

| pH | 4.47A | 3.95B | 3.76C | 3.70CD | 3.61D | 3.59D | 0.072 | <0.001 |

| 乳酸Lactic acid (LA, %DM) | 0.64A | 4.29A | 5.80A | 7.85A | 12.40A | 13.20A | 1.887 | 0.438 |

| 乙酸Acetic acid (AA, %DM) | 0.15C | 0.78BC | 1.13BC | 1.90ABC | 2.34AB | 3.19A | 0.276 | 0.002 |

| 乳乙比LA/AA | 4.45A | 5.76A | 5.43A | 4.13A | 3.17A | 4.13A | 0.449 | 0.518 |

| 丙酸Propionic acid (%DM) | 0.04BC | 0.02BC | 0.00C | 0.03BC | 0.06B | 0.11A | 0.009 | <0.001 |

| 正丁酸n-butyric acid (n-BA, %DM) | ND | ND | ND | ND | ND | ND | - | - |

| 异丁酸Isobutyric acid (IBA, %DM) | ND | ND | ND | ND | ND | ND | - | - |

| 挥发性脂肪酸Volatile fatty acid (VFA, %DM) | 0.19C | 0.79BC | 1.14BC | 1.93ABC | 2.40AB | 3.30A | 0.173 | 0.002 |

| 乙醇Ethanol (%DM) | 0.09B | 0.04B | 0.08B | 0.16AB | 0.23AB | 0.33A | 0.027 | 0.002 |

| 1,2-丙二醇1,2-propanediol (%DM) | ND | ND | ND | ND | ND | ND | - | - |

| 干物质Dry matter (%FW) | 32.3A | 31.1AB | 29.6B | 29.5B | 29.1B | 29.5B | 0.315 | 0.006 |

| 水溶性碳水化合物WSC (%DM) | 28.2A | 25.1A | 25.2A | 19.2B | 18.2BC | 14.4C | 1.174 | <0.001 |

| 氨态氮Ammonia nitrogen (NH3-N, %TN) | 6.48A | 7.68A | 7.75A | 7.68A | 8.01A | 8.51A | 0.230 | 0.245 |

项目 Item | 贮藏时间Ensiling time (d) | SEM | P值 P-value | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 7 | 15 | 30 | 60 | |||

| 乳酸菌LAB | 8.58AB | 9.21A | 9.16A | 9.06A | 9.47A | 8.07B | 0.128 | 0.003 |

| 好氧性细菌Aerobic bacteria | 7.28A | 5.22AB | 3.54BC | 3.38BC | 2.09C | <2.00C | 0.524 | <0.001 |

| 酵母菌Yeasts | 7.74 | 4.60 | 3.94 | 2.87 | <2.00 | ND | - | - |

| 霉菌Molds | 5.22 | 3.22 | <2.00 | ND | ND | ND | - | - |

| 肠杆菌Enterobacteria | 6.03 | 4.55 | 2.20 | ND | ND | ND | - | - |

表3 贮藏时间对甜高粱青贮饲料微生物数量的影响

Table 3 Effects of storage time on the microbial number of SSS (lg CFU·g-1 FM)

项目 Item | 贮藏时间Ensiling time (d) | SEM | P值 P-value | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 7 | 15 | 30 | 60 | |||

| 乳酸菌LAB | 8.58AB | 9.21A | 9.16A | 9.06A | 9.47A | 8.07B | 0.128 | 0.003 |

| 好氧性细菌Aerobic bacteria | 7.28A | 5.22AB | 3.54BC | 3.38BC | 2.09C | <2.00C | 0.524 | <0.001 |

| 酵母菌Yeasts | 7.74 | 4.60 | 3.94 | 2.87 | <2.00 | ND | - | - |

| 霉菌Molds | 5.22 | 3.22 | <2.00 | ND | ND | ND | - | - |

| 肠杆菌Enterobacteria | 6.03 | 4.55 | 2.20 | ND | ND | ND | - | - |

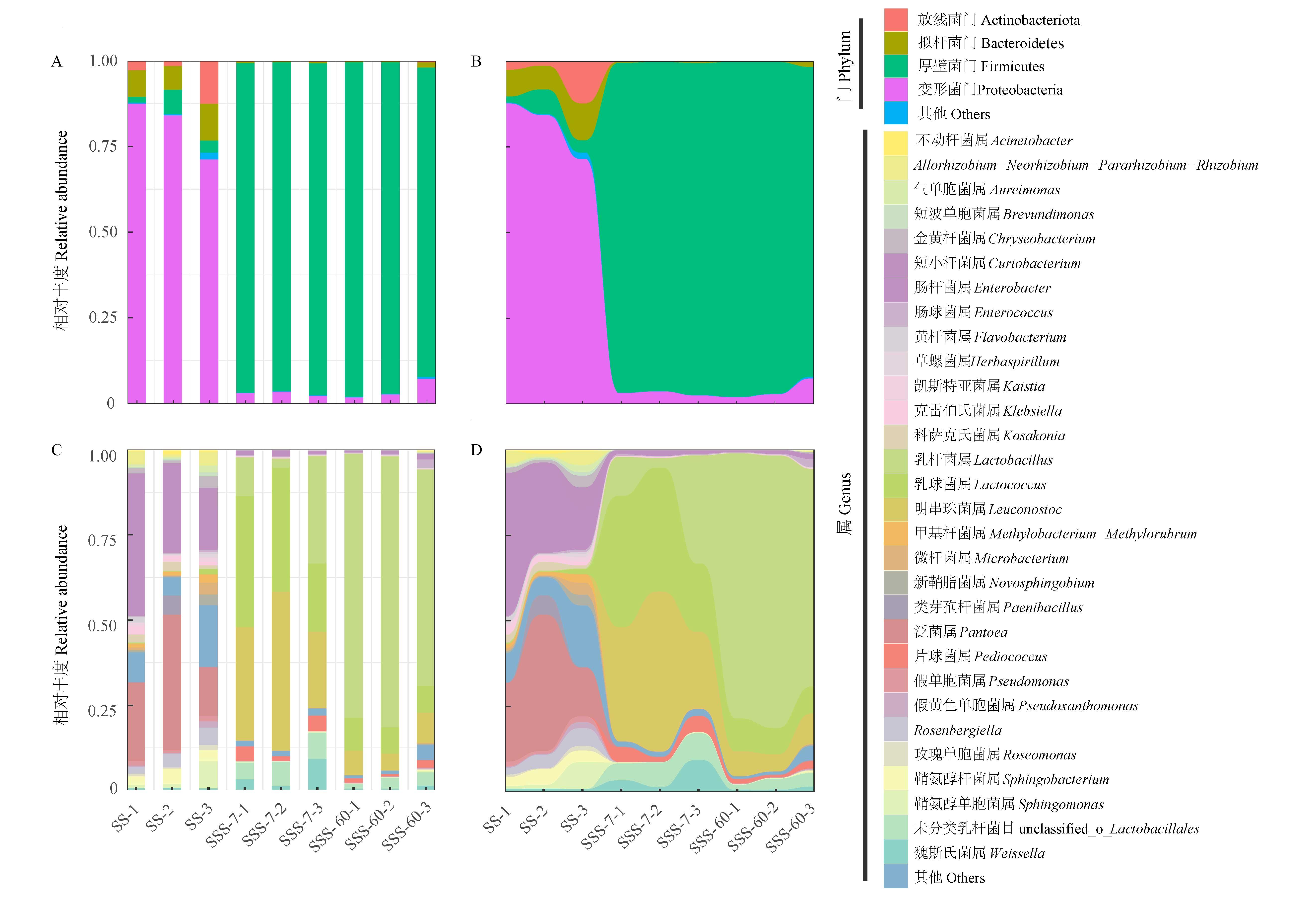

图3 门和属水平上细菌群落相对丰度条形图及细菌群落演替河流图

Fig.3 The community bar plots of bacterial community and the stream graph showing the bacterial community successions at the phylum and genus level

图4 门和属水平上细菌群落多物种差异检验*: P<0.05; **: P<0.01; ***: P<0.001; 下同The same below.

Fig.4 Multispecies difference test of bacterial community at the phylum and genus leve

图5 甜高粱青贮过程中化学成分、发酵产物与主要菌属的斯皮尔曼相关性红色方格表示正相关(0<r<1),蓝色方格表示负相关(-1<r<0) Red squares refer to positive correlation (0<r<1), whereas blue squares refer to negative correlation (-1<r<0); LA: 乳酸Lactic acid; PA: 丙酸Propionic acid; Ethanol: 乙醇; AA: 乙酸Acetic acid; VFA: 挥发性脂肪酸Volatile fatty acid; Enterobacteria:肠杆菌; LAB: 乳酸菌Lactic acid bacteria; Yeast: 酵母菌; Aerobic bacteria:好氧性细菌; WSC: 水溶性碳水化合物Water-soluble carbohydrates; Molds: 霉菌.

Fig.5 Spearman’s correlation of bacterial genera (top 30 genera), chemical components and fermentation products during ensiling of sweet sorghum

图6 基于16S rRNA数据预测的1、2和3级通路水平对应的KEGG功能谱方格颜色深浅表示相应功能的丰度值大小Color squares refer to the abundance of function profiles.

Fig.6 16S rRNA gene-predicted KEGG function profiles at pathway level 1, level 2 and level 3

| 1 | Velmurugan B, Narra M, Rudakiya D M, et al. Sweet sorghum: a potential resource for bioenergy production//Kumar R P, Gnansounou E, Raman J K, et al. Refining biomass residues for sustainable energy and bioproducts. New York: Academic Press, 2020: 215-242. |

| 2 | Bassam E L, Jakob K. Sweet sorghum, a sustainable crop for energy production in Europe-Results of 10 years experiments (1985-1995)//Proceeding of first international sweet sorghum conference. Beijing: Chinese Academy of Sciences, 1997: 88-110. |

| 3 | Davila-Gomez F J, Chuck-Hernandez C, Perez-Carrillo E, et al. Evaluation of bioethanol production from five different varieties of sweet and forage sorghums (Sorghum bicolor (L.) Moench). Industrial Crops and Products, 2011, 33(3): 611-616. |

| 4 | Bhat B V. Breeding forage sorghum//Aruna C, Visarada K B R S, Bhat B V, et al. Breeding sorghum for diverse end uses. Oxford: Woodhead Publishing, 2019: 175-191. |

| 5 | Chen L. Study on the fermentation quality, aerobic stability and in vitro ruminal fermentation characteristics of sweet sorghum-alfalfa silages. Nanjing: Nanjing Agricultural University, 2018. |

| 陈雷. 甜高粱和紫花苜蓿混合青贮发酵品质、有氧稳定性和体外瘤胃发酵特性的研究. 南京: 南京农业大学, 2018. | |

| 6 | Li C X, Feng H S, Zhao Y G, et al. Sweet sorghum cultivation techniques. Acta Agrestia Sinica, 2013, 21(1): 114-122. |

| 李春喜, 冯海生, 赵延贵, 等. 甜高粱栽培技术研究. 草地学报, 2013, 21(1): 114-122. | |

| 7 | Tao Y, Sun Q, Li F, et al. Comparative analysis of ensiling characteristics and protein degradation of alfalfa silage prepared with corn or sweet sorghum in semiarid region of Inner Mongolia. Animal Science Journal, 2020, 91(1): e13321. |

| 8 | Wu X, Staggenborg S, Propheter J L, et al. Features of sweet sorghum juice and their performance in ethanol fermentation. Industrial Crops and Products, 2010, 31(1): 164-170. |

| 9 | Umakanth A V, Kumar A A, Vermerris W, et al. Sweet sorghum for biofuel industry//Aruna C, Visarada K B R S, Bhat B V, et al. Breeding sorghum for diverse end uses. Oxford: Woodhead Publishing, 2019: 255-270. |

| 10 | McDonald P, Henderson A R, Heron S J E. The biochemistry of silage (the second edition). Bucks: Chalcombe Publications, 1991. |

| 11 | Keshri J, Chen Y, Pinto R, et al. Bacterial dynamics of wheat silage. Frontiers in Microbiology, 2019, 10: 1532. |

| 12 | McAllister T A, Duniere L, Drouin P, et al. Silage review: Using molecular approaches to define the microbial ecology of silage. Journal of Dairy Science, 2018, 101(5): 4060-4074. |

| 13 | Asshauer K P, Wemheuer B, Daniel R, et al. Tax4Fun: Predicting functional profiles from metagenomic 16S rRNA data. Bioinformatics, 2015, 31(17): 2882-2884. |

| 14 | Kanehisa M, Goto S. KEGG: Kyoto encyclopedia of genes and genomes. Nucleic Acids Research, 2000, 28(1): 27-30. |

| 15 | Broderick G A, Kang J H. Automated simultaneous determination of ammonia and total amino acids in ruminal fluid and in vitro media. Journal of Dairy Science, 1980, 63(1): 64-75. |

| 16 | Zhao J, Dong Z, Li J, et al. Ensiling as pretreatment of rice straw: The effect of hemicellulase and Lactobacillus plantarum on hemicellulose degradation and cellulose conversion. Bioresource Technology, 2018, 266: 158-165. |

| 17 | Thomas T A. An automated procedure for the determination of soluble carbohydrates in herbage. Journal of the Science of Food and Agriculture, 1977, 28(7): 639-642. |

| 18 | Van Soest P J, Robertson J B, Lewis B A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. Journal of Dairy Science, 1991, 74(10): 3583-3597. |

| 19 | Zhao J, Yin X, Wang S, et al. Separating the effects of chemical and microbial factors on fermentation quality and bacterial community of napier grass silage by using gamma-ray irradiation and epiphytic microbiota transplantation. Animal Feed Science and Technology, 2021, 280: 115082. |

| 20 | Zhao J, Yin X, Dong Z, et al. Using gamma-ray irradiation and epiphytic microbiota inoculation to separate the effects of chemical and microbial factors on fermentation quality and bacterial community of ensiled Pennisetum giganteum. Journal of Applied Microbiology, 2022, 132(3): 1675-1686. |

| 21 | Kung L, Shaver R. Interpretation and use of silage fermentation analysis reports. Focus on Forage, 2001, 3(13): 1-5. |

| 22 | Kung L, Shaver R D, Grant R J, et al. Silage review: Interpretation of chemical, microbial, and organoleptic components of silages. Journal of Dairy Science, 2018, 101(5): 4020-4033. |

| 23 | Dong Z, Shao T, Li J, et al. Effect of alfalfa microbiota on fermentation quality and bacterial community succession in fresh or sterile napier grass silages. Journal of Dairy Science, 2020, 103(5): 4288-4301. |

| 24 | Mendez-Garcia C, Pelaez A I, Mesa V, et al. Microbial diversity and metabolic networks in acid mine drainage habitats. Frontiers in Microbiology, 2015, 6: 475. |

| 25 | Muck R E. Recent advances in silage microbiology. Agricultural and Food Science, 2013, 22(1): 3-15. |

| 26 | Cai Y, Benno Y, Ogawa M, et al. Influence of Lactobacillus spp. from an inoculant and of Weissella and Leuconostoc spp. from forage crops on silage fermentation. Applied and Environmental Microbiology, 1998, 64(8): 2982-2987. |

| 27 | Yuan X, Dong Z, Li J, et al. Microbial community dynamics and their contributions to organic acid production during the early stage of the ensiling of napier grass (Pennisetum purpureum). Grass and Forage Science, 2019, 75(1): 37-44. |

| 28 | Yang L, Yuan X, Li J, et al. Dynamics of microbial community and fermentation quality during ensiling of sterile and nonsterile alfalfa with or without Lactobacillus plantarum inoculant. Bioresource Technology, 2019, 275: 280-287. |

| 29 | Bai J, Ding Z, Ke W, et al. Different lactic acid bacteria and their combinations regulated the fermentation process of ensiled alfalfa: Ensiling characteristics, dynamics of bacterial community and their functional shifts. Microbial Biotechnology, 2021, 14(3): 1171-1182. |

| 30 | Flythe M D, Russell J B. The effect of pH and a bacteriocin (bovicin HC5) on Clostridium sporogenes MD1, a bacterium that has the ability to degrade amino acids in ensiled plant materials. FEMS Microbiology Ecology, 2004, 47(2): 215-222. |

| 31 | Liu Q, Wu J, Shao T. Roles of microbes and lipolytic enzymes in changing the fatty acid profile, α-tocopherol and β-carotene of whole-crop oat silages during ensiling and after exposure to air. Animal Feed Science and Technology, 2019, 253: 81-92. |

| 32 | Pessione A, Lamberti C, Pessione E. Proteomics as a tool for studying energy metabolism in lactic acid bacteria. Molecular BioSystems, 2010, 6(8): 1419-1430. |

| 33 | Xu D, Wang N, Rinne M, et al. The bacterial community and metabolome dynamics and their interactions modulate fermentation process of whole crop corn silage prepared with or without inoculants. Microbial Biotechnology, 2021, 14(2): 561-576. |

| 34 | Kilstrup M, Hammer K, Ruhdal J P, et al. Nucleotide metabolism and its control in lactic acid bacteria. FEMS Microbiology Reviews, 2005, 29(3): 555-590. |

| 35 | Banfalvi G. Conversion of oxidative energy to reductive power in the citrate cycle. Biochemical Education, 1991, 19(1): 24-26. |

| 36 | Abdel-Rahman M A, Tashiro Y, Sonomoto K. Lactic acid production from lignocellulose-derived sugars using lactic acid bacteria: Overview and limits. Journal of Biotechnology, 2011, 156(4): 286-301. |

| [1] | 凌文卿, 张磊, 李珏, 冯启贤, 李妍, 周燚, 刘一佳, 阳伏林, 周晶. 布氏乳杆菌和不同糖类联用对紫花苜蓿青贮营养成分、发酵品质、瘤胃降解率及有氧稳定性的影响[J]. 草业学报, 2023, 32(7): 122-134. |

| [2] | 党浩千, 覃娟清, 郭宇康, 张富, 王迎港, 刘庆华. 不同添加剂发酵笋壳对湖羊生产性能及瘤胃发酵的影响[J]. 草业学报, 2023, 32(7): 135-148. |

| [3] | 梁佳, 胡朝阳, 谢志明, 马刘峰, 陈芸, 方志刚. 外源褪黑素缓解甜高粱幼苗干旱胁迫的生理效应[J]. 草业学报, 2023, 32(7): 206-215. |

| [4] | 梁梦琪, 武齐丰, 邵涛, 吴艾丽, 刘秦华. 添加剂对多花黑麦草青贮发酵品质、α-生育酚和β-胡萝卜素含量的影响[J]. 草业学报, 2023, 32(5): 180-189. |

| [5] | 王腾飞, 王斌, 邓建强, 李满有, 倪旺, 冯琴, 妥昀昀, 兰剑. 宁夏干旱区滴灌条件下拉巴豆不同播种量与甜高粱混播饲草生产性能研究[J]. 草业学报, 2023, 32(3): 30-40. |

| [6] | 付东青, 贾春英, 张力, 张凡凡, 马春晖. 南疆干旱灌溉区青贮玉米农艺性状和发酵品质动态分析及评价[J]. 草业学报, 2022, 31(8): 111-125. |

| [7] | 李影正, 程榆林, 徐璐璐, 李万松, 严旭, 李晓锋, 何如钰, 周阳, 郑军军, 汪星宇, 张德龙, 程明军, 夏运红, 何建美, 唐祈林. 不同玉米品种(系)的全株、果穗与秸秆青贮特性比较[J]. 草业学报, 2022, 31(8): 144-156. |

| [8] | 吴永杰, 丁浩, 邵涛, 赵杰, 董东, 代童童, 尹雪敬, 宗成, 李君风. 酶制剂对水稻秸秆青贮发酵品质及体外消化特性的影响[J]. 草业学报, 2022, 31(8): 167-177. |

| [9] | 姚露花, 綦才, 杨建峰, 郭彦军. 种子引发对甜高粱角质层蜡质及其抗性的影响[J]. 草业学报, 2022, 31(7): 185-196. |

| [10] | 李君风, 赵杰, 唐小月, 代童童, 董东, 宗成, 邵涛. 瘤胃纤维素降解菌系对灭菌水稻秸秆结构性碳水化合物降解的影响[J]. 草业学报, 2022, 31(7): 85-95. |

| [11] | 郭香, 吴硕, 郑明扬, 陈德奎, 邹璇, 陈晓阳, 周玮, 张庆. 添加黄梁木叶和壳寡糖对甘蔗梢青贮饲料发酵品质及有氧稳定性的影响[J]. 草业学报, 2022, 31(6): 202-210. |

| [12] | 张欢, 牟怡晓, 张桂杰. 添加枸杞副产物对紫花苜蓿青贮发酵品质及微生物多样性的影响[J]. 草业学报, 2022, 31(4): 136-144. |

| [13] | 杨德智, 王晨, 侯明杰, 王虎成. 饲用甜高粱和全株玉米青贮对肉羊前胃微生态的影响[J]. 草业学报, 2022, 31(4): 145-154. |

| [14] | 王志恒, 魏玉清, 赵延蓉, 王悦娟. 基于转录组学比较研究甜高粱幼苗响应干旱和盐胁迫的生理特征[J]. 草业学报, 2022, 31(3): 71-84. |

| [15] | 李海萍, 关皓, 贾志锋, 刘文辉, 马祥, 刘勇, 汪辉, 马力, 周青平. 抗冻融乳酸菌的筛选及其对燕麦青贮品质和有氧稳定性的影响[J]. 草业学报, 2022, 31(12): 158-170. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||