ISSN 1004-5759 CN 62-1105/S

草业学报 ›› 2025, Vol. 34 ›› Issue (6): 227-238.DOI: 10.11686/cyxb2024347

• 研究论文 • 上一篇

匡宗洋1( ), 穆麟1, 魏岚1, 郭阳1, 胥贵1, 陈瑶1, 石雪云1, 魏仲珊2, 张志飞1(

), 穆麟1, 魏岚1, 郭阳1, 胥贵1, 陈瑶1, 石雪云1, 魏仲珊2, 张志飞1( )

)

收稿日期:2024-09-09

修回日期:2024-10-31

出版日期:2025-06-20

发布日期:2025-04-03

通讯作者:

张志飞

作者简介:Corresponding author. E-mail: zhangzf@hunau.edu.cn基金资助:

Zong-yang KUANG1( ), Lin MU1, Lan WEI1, Yang GUO1, Gui XU1, Yao CHEN1, Xue-yun SHI1, Zhong-shan WEI2, Zhi-fei ZHANG1(

), Lin MU1, Lan WEI1, Yang GUO1, Gui XU1, Yao CHEN1, Xue-yun SHI1, Zhong-shan WEI2, Zhi-fei ZHANG1( )

)

Received:2024-09-09

Revised:2024-10-31

Online:2025-06-20

Published:2025-04-03

Contact:

Zhi-fei ZHANG

摘要:

本试验基于南方玉米和大豆带状间作栽培模式,旨在探究不同混合比例和乳酸菌添加对玉米和大豆混合青贮品质及有氧稳定性的影响。将全株玉米和大豆分别刈割,粉碎后按比例进行添加剂混合青贮,设计双因素完全随机试验,因素A为玉米与大豆质量混合比例,分别为1∶0(A1)、2∶1(A2)、1∶1(A3)、1∶2(A4)和0∶1(A5);因素B为乳酸菌添加类型,分别为:布氏乳杆菌(LB)、植物乳杆菌(LP)、不添加乳酸菌(L0)。发酵60 d后分析营养品质、发酵品质和有氧稳定性。结果表明:不同混合比例和乳酸菌添加对玉米-大豆混合青贮的粗蛋白(CP)、中性洗涤纤维(NDF)、酸性洗涤木质素(ADL)、粗脂肪(EE)、粗灰分(Ash)含量、pH值、乳酸(LA)、乙酸(AA)、丙酸(PA)含量、氨态氮/总氮(NH3-N/TN)及有氧稳定时长均有极显著的交互作用(P<0.01)。A2和A3混合处理组的中性洗涤纤维、酸性洗涤纤维(ADF)及乳酸含量显著优于其他3个混合处理组(P<0.05)。与L0组相比,LP组中除A4混合处理组外,其他混合处理组的乳酸含量显著增加(P<0.05),粗灰分含量显著降低(P<0.05),除A5混合处理组外,其他混合处理组的pH值显著降低(P<0.05);LB组中所有混合处理组的酸性洗涤木质素显著降低(P<0.05),A1、A2和A3混合处理组的乙酸含量显著增加(P<0.05),同时有氧稳定时长增加。将各混合青贮处理组的11项核心指标进行灰色关联分析表明,所有处理组中加权关联度排名前三的为:A2LP、A3LB和A1LP,青贮效果好。综上,建议南方地区全株玉米-大豆混合青贮中,全株大豆质量占比应小于等于全株玉米质量占比,并添加植物乳杆菌(LP)提高青贮发酵品质。

匡宗洋, 穆麟, 魏岚, 郭阳, 胥贵, 陈瑶, 石雪云, 魏仲珊, 张志飞. 不同混合比例和乳酸菌添加对全株玉米和大豆混合青贮品质及有氧稳定性的影响[J]. 草业学报, 2025, 34(6): 227-238.

Zong-yang KUANG, Lin MU, Lan WEI, Yang GUO, Gui XU, Yao CHEN, Xue-yun SHI, Zhong-shan WEI, Zhi-fei ZHANG. Effects of different mixture ratios and lactic acid bacteria on the quality and aerobic stability of mixed silage made from whole maize (Zea mays) and soybean (Glycine max) plants[J]. Acta Prataculturae Sinica, 2025, 34(6): 227-238.

青贮材料 Ensilage materials | 干物质 Dry matter (%FW) | 粗蛋白 Crude protein (%DM) | 可溶性碳水化合物 Water soluble carbohydrate (%DM) | 中性洗涤纤维 Neutral detergent fiber (%DM) | 酸性洗涤纤维 Acid detergent fiber (%DM) | 粗脂肪 Ether extract (%DM) | 粗灰分 Crude ash (%DM) |

|---|---|---|---|---|---|---|---|

| 全株玉米Whole-plant maize | 37.84±0.33 | 9.81±0.37 | 6.74±0.29 | 45.10±1.00 | 19.90±0.98 | 1.29±0.18 | 4.92±0.06 |

| 全株大豆Whole-plant soybean | 29.85±0.37 | 20.74±0.36 | 5.56±0.04 | 43.42±1.47 | 28.15±0.94 | 7.11±0.56 | 9.30±0.13 |

表1 青贮原料化学成分

Table 1 Chemical composition of ensilage materials

青贮材料 Ensilage materials | 干物质 Dry matter (%FW) | 粗蛋白 Crude protein (%DM) | 可溶性碳水化合物 Water soluble carbohydrate (%DM) | 中性洗涤纤维 Neutral detergent fiber (%DM) | 酸性洗涤纤维 Acid detergent fiber (%DM) | 粗脂肪 Ether extract (%DM) | 粗灰分 Crude ash (%DM) |

|---|---|---|---|---|---|---|---|

| 全株玉米Whole-plant maize | 37.84±0.33 | 9.81±0.37 | 6.74±0.29 | 45.10±1.00 | 19.90±0.98 | 1.29±0.18 | 4.92±0.06 |

| 全株大豆Whole-plant soybean | 29.85±0.37 | 20.74±0.36 | 5.56±0.04 | 43.42±1.47 | 28.15±0.94 | 7.11±0.56 | 9.30±0.13 |

项目 Item | 指标 Index | 显著性 Significance | 大豆混合占比 Soybean mix proportion | ||

|---|---|---|---|---|---|

混合比例 Mixing ratio | 乳酸菌剂Lactic acid bacteria agent | 交互作用 Interactions | 相关性 Correlation# | ||

营养品质 Nutrient quality | 干物质Dry matter (%FW) | ** | ** | NS | -0.862** |

| 粗蛋白Crude protein (%DM) | ** | * | ** | 0.986** | |

| 可溶性碳水化合物Water soluble carbohydrate (%DM) | ** | ** | NS | -0.863** | |

| 中性洗涤纤维Neutral detergent fiber (%DM) | ** | ** | ** | -0.024 | |

| 酸性洗涤纤维Acid detergent fiber (%DM) | ** | ** | NS | 0.804** | |

| 酸性洗涤木质素Acid detergent lignin (%DM) | ** | ** | ** | 0.781** | |

| 粗脂肪Ether extract (%DM) | ** | ** | ** | 0.988** | |

| 粗灰分Crude ash (%DM) | ** | ** | ** | 0.977** | |

发酵品质 Fermentation quality | pH值pH value | ** | ** | ** | 0.876** |

| 乳酸Lactic acid (%DM) | ** | ** | ** | -0.447** | |

| 乙酸Acetic acid (%DM) | ** | ** | ** | 0.715** | |

| 丙酸Propionic acid (%DM) | ** | ** | ** | 0.698** | |

| 丁酸Butyric acid (%DM) | ** | NS | NS | 0.488** | |

| 氨态氮/总氮Ammonia-N/total-N (%) | ** | ** | ** | 0.796** | |

| 有氧稳定时长Aerobic stability time (h) | ** | ** | ** | 0.758** | |

表2 全株玉米-大豆混合青贮饲料指标的主体间效应检验

Table 2 Inter-subject effect test of whole maize-soybean mixed silage indexes

项目 Item | 指标 Index | 显著性 Significance | 大豆混合占比 Soybean mix proportion | ||

|---|---|---|---|---|---|

混合比例 Mixing ratio | 乳酸菌剂Lactic acid bacteria agent | 交互作用 Interactions | 相关性 Correlation# | ||

营养品质 Nutrient quality | 干物质Dry matter (%FW) | ** | ** | NS | -0.862** |

| 粗蛋白Crude protein (%DM) | ** | * | ** | 0.986** | |

| 可溶性碳水化合物Water soluble carbohydrate (%DM) | ** | ** | NS | -0.863** | |

| 中性洗涤纤维Neutral detergent fiber (%DM) | ** | ** | ** | -0.024 | |

| 酸性洗涤纤维Acid detergent fiber (%DM) | ** | ** | NS | 0.804** | |

| 酸性洗涤木质素Acid detergent lignin (%DM) | ** | ** | ** | 0.781** | |

| 粗脂肪Ether extract (%DM) | ** | ** | ** | 0.988** | |

| 粗灰分Crude ash (%DM) | ** | ** | ** | 0.977** | |

发酵品质 Fermentation quality | pH值pH value | ** | ** | ** | 0.876** |

| 乳酸Lactic acid (%DM) | ** | ** | ** | -0.447** | |

| 乙酸Acetic acid (%DM) | ** | ** | ** | 0.715** | |

| 丙酸Propionic acid (%DM) | ** | ** | ** | 0.698** | |

| 丁酸Butyric acid (%DM) | ** | NS | NS | 0.488** | |

| 氨态氮/总氮Ammonia-N/total-N (%) | ** | ** | ** | 0.796** | |

| 有氧稳定时长Aerobic stability time (h) | ** | ** | ** | 0.758** | |

混合 比例Mixing ratio | 乳酸菌剂 Lactic acid bacteria agent | 干物质 Dry matter (%FW) | 粗蛋白 Crude protein (%DM) | 可溶性碳水化合物 Water soluble carbohydrate (%DM) | 中性洗涤纤维 Neutral detergent fiber (%DM) | 酸性洗涤纤维 Acid detergent fiber (%DM) | 酸性洗涤木质素 Acid detergent lignin (%DM) | 粗脂肪 Ether extract (%DM) | 粗灰分 Crude ash (%DM) |

|---|---|---|---|---|---|---|---|---|---|

| A1 | LB | 33.99±0.42Ab | 8.34±0.10Eb | 1.42±0.14Aa | 48.58±0.68Ab | 23.49±1.90Cab | 1.56±0.21Db | 2.18±0.12Ea | 4.50±0.02Eb |

| LP | 36.53±0.39Aa | 8.57±0.22Eb | 1.18±0.09Aa | 48.21±1.27Ab | 21.05±1.59Db | 1.19±0.02Ec | 1.25±0.10Eb | 4.04±0.06Ec | |

| L0 | 34.49±0.63Ab | 9.38±0.23Ea | 1.43±0.13Aa | 51.95±1.13Aa | 24.89±0.39Ca | 2.39±0.12Ea | 2.27±0.04Ea | 4.73±0.03Ea | |

| A2 | LB | 32.63±0.47Bb | 14.09±0.08Da | 1.17±0.00Ba | 49.57±1.67Aa | 24.61±0.33Ca | 2.51±0.10Cb | 5.65±0.29Da | 6.34±0.07Da |

| LP | 34.99±0.70Ba | 13.91±0.75Da | 1.06±0.02Ab | 43.50±1.14Cb | 21.43±0.33Db | 1.96±0.06Dc | 4.31±0.25Db | 5.36±0.04Dc | |

| L0 | 33.90±1.10ABab | 13.55±0.30Da | 1.25±0.07Ba | 49.73±2.05ABa | 24.75±2.61Ca | 3.33±0.52Da | 4.80±0.05Db | 5.63±0.03Db | |

| A3 | LB | 32.03±0.66Bb | 17.20±0.09Ca | 0.95±0.07Ca | 43.48±0.43Ba | 23.37±1.13Ca | 2.86±0.20BCb | 6.97±0.53Ca | 6.80±0.06Ca |

| LP | 34.24±0.83Ba | 15.63±0.15Cb | 0.92±0.04Ba | 42.99±1.61Cb | 24.45±1.17Ca | 3.97±0.22Ca | 6.56±0.19Ca | 6.04±0.03Cc | |

| L0 | 33.56±0.74ABab | 15.31±0.03Cc | 0.90±0.04Ca | 44.04±1.36Ca | 23.92±0.82Ca | 3.85±0.30Ca | 6.68±0.20Ca | 6.25±0.11Cb | |

| A4 | LB | 31.86±0.72Bb | 19.07±0.30Ba | 0.89±0.07Ca | 51.19±1.27Aa | 28.25±1.61Ba | 3.99±0.35Ab | 8.19±0.16Ba | 7.34±0.02Ba |

| LP | 32.46±0.31Ca | 18.54±0.07Bb | 0.85±0.05BCa | 46.87±0.64ABb | 27.55±0.19Ba | 4.63±0.09Bb | 7.63±0.17Bb | 7.14±0.01Bb | |

| L0 | 32.13±1.06Ba | 17.46±0.04Bc | 0.84±0.04Ca | 47.62±1.53Bb | 29.89±0.60Ba | 6.27±0.32Ba | 7.24±0.01Bc | 7.07±0.04Bc | |

| A5 | LB | 28.69±0.10Cb | 21.46±0.23Ab | 0.83±0.02Ca | 49.86±1.05Aa | 32.48±1.75Aab | 3.14±0.33Bc | 11.41±0.17Aa | 9.19±0.13Aab |

| LP | 29.37±0.13Da | 21.89±0.08Aa | 0.75±0.05Ca | 45.30±0.97BCb | 29.97±0.63Ab | 6.38±0.18Ab | 10.21±0.02Aa | 9.03±0.02Ab | |

| L0 | 29.09±0.27Cab | 21.65±0.08Aab | 0.79±0.04Ca | 51.81±0.52Aa | 34.80±0.21Aa | 8.60±0.13Aa | 11.33±0.20Aa | 9.36±0.05Aa |

表3 全株玉米-大豆混合青贮营养品质

Table 3 Nutritional quality of whole maize-soybean mixed silage

混合 比例Mixing ratio | 乳酸菌剂 Lactic acid bacteria agent | 干物质 Dry matter (%FW) | 粗蛋白 Crude protein (%DM) | 可溶性碳水化合物 Water soluble carbohydrate (%DM) | 中性洗涤纤维 Neutral detergent fiber (%DM) | 酸性洗涤纤维 Acid detergent fiber (%DM) | 酸性洗涤木质素 Acid detergent lignin (%DM) | 粗脂肪 Ether extract (%DM) | 粗灰分 Crude ash (%DM) |

|---|---|---|---|---|---|---|---|---|---|

| A1 | LB | 33.99±0.42Ab | 8.34±0.10Eb | 1.42±0.14Aa | 48.58±0.68Ab | 23.49±1.90Cab | 1.56±0.21Db | 2.18±0.12Ea | 4.50±0.02Eb |

| LP | 36.53±0.39Aa | 8.57±0.22Eb | 1.18±0.09Aa | 48.21±1.27Ab | 21.05±1.59Db | 1.19±0.02Ec | 1.25±0.10Eb | 4.04±0.06Ec | |

| L0 | 34.49±0.63Ab | 9.38±0.23Ea | 1.43±0.13Aa | 51.95±1.13Aa | 24.89±0.39Ca | 2.39±0.12Ea | 2.27±0.04Ea | 4.73±0.03Ea | |

| A2 | LB | 32.63±0.47Bb | 14.09±0.08Da | 1.17±0.00Ba | 49.57±1.67Aa | 24.61±0.33Ca | 2.51±0.10Cb | 5.65±0.29Da | 6.34±0.07Da |

| LP | 34.99±0.70Ba | 13.91±0.75Da | 1.06±0.02Ab | 43.50±1.14Cb | 21.43±0.33Db | 1.96±0.06Dc | 4.31±0.25Db | 5.36±0.04Dc | |

| L0 | 33.90±1.10ABab | 13.55±0.30Da | 1.25±0.07Ba | 49.73±2.05ABa | 24.75±2.61Ca | 3.33±0.52Da | 4.80±0.05Db | 5.63±0.03Db | |

| A3 | LB | 32.03±0.66Bb | 17.20±0.09Ca | 0.95±0.07Ca | 43.48±0.43Ba | 23.37±1.13Ca | 2.86±0.20BCb | 6.97±0.53Ca | 6.80±0.06Ca |

| LP | 34.24±0.83Ba | 15.63±0.15Cb | 0.92±0.04Ba | 42.99±1.61Cb | 24.45±1.17Ca | 3.97±0.22Ca | 6.56±0.19Ca | 6.04±0.03Cc | |

| L0 | 33.56±0.74ABab | 15.31±0.03Cc | 0.90±0.04Ca | 44.04±1.36Ca | 23.92±0.82Ca | 3.85±0.30Ca | 6.68±0.20Ca | 6.25±0.11Cb | |

| A4 | LB | 31.86±0.72Bb | 19.07±0.30Ba | 0.89±0.07Ca | 51.19±1.27Aa | 28.25±1.61Ba | 3.99±0.35Ab | 8.19±0.16Ba | 7.34±0.02Ba |

| LP | 32.46±0.31Ca | 18.54±0.07Bb | 0.85±0.05BCa | 46.87±0.64ABb | 27.55±0.19Ba | 4.63±0.09Bb | 7.63±0.17Bb | 7.14±0.01Bb | |

| L0 | 32.13±1.06Ba | 17.46±0.04Bc | 0.84±0.04Ca | 47.62±1.53Bb | 29.89±0.60Ba | 6.27±0.32Ba | 7.24±0.01Bc | 7.07±0.04Bc | |

| A5 | LB | 28.69±0.10Cb | 21.46±0.23Ab | 0.83±0.02Ca | 49.86±1.05Aa | 32.48±1.75Aab | 3.14±0.33Bc | 11.41±0.17Aa | 9.19±0.13Aab |

| LP | 29.37±0.13Da | 21.89±0.08Aa | 0.75±0.05Ca | 45.30±0.97BCb | 29.97±0.63Ab | 6.38±0.18Ab | 10.21±0.02Aa | 9.03±0.02Ab | |

| L0 | 29.09±0.27Cab | 21.65±0.08Aab | 0.79±0.04Ca | 51.81±0.52Aa | 34.80±0.21Aa | 8.60±0.13Aa | 11.33±0.20Aa | 9.36±0.05Aa |

混合比例 Mixing ratio | 乳酸菌剂 Lactic acid bacteria agent | pH值 pH value | 乳酸 Lactic acid (%DM) | 乙酸 Acetic acid (%DM) | 丙酸 Propionic acid (%DM) | 丁酸 Butyric acid (%DM) | 氨态氮/总氮 Ammonia-N/ total-N (%) |

|---|---|---|---|---|---|---|---|

| A1 | LB | 4.01±0.00Ea | 5.02±0.41Ac | 2.61±0.94Ba | ND | 0.03±0.02Aa | 8.65±0.31Ba |

| LP | 3.60±0.01Ec | 10.42±0.14Ba | 0.39±0.01Db | 0.21±0.01Cb | ND | 4.63±0.41Cb | |

| L0 | 3.75±0.01Eb | 7.56±0.30Bb | 1.04±0.28Cb | 0.39±0.01Ba | ND | 4.72±0.31Cb | |

| A2 | LB | 4.27±0.00Da | 3.22±0.47Bc | 3.17±0.51ABa | 0.14±0.02Ba | ND | 8.40±0.15Ba |

| LP | 3.79±0.01Dc | 14.94±1.18Aa | 0.52±0.04Db | 0.15±0.11Ca | ND | 4.62±0.34Cb | |

| L0 | 3.93±0.01Db | 9.97±0.57Ab | 1.28±0.35Cb | 0.30±0.01Ba | ND | 5.24±0.55Cb | |

| A3 | LB | 4.40±0.00Ca | 4.83±0.60ABc | 2.83±0.21Ba | 0.14±0.01Bb | ND | 8.42±0.62Ba |

| LP | 3.91±0.02Cc | 14.60±6.88Aa | 0.78±0.04Cc | 1.26±0.22Ba | ND | 6.87±0.15Ba | |

| L0 | 4.07±0.01Cb | 10.31±0.51Ab | 2.39±0.08Bb | 0.29±0.02Bab | ND | 7.07±0.93Ba | |

| A4 | LB | 4.50±0.02Ba | 5.32±1.44Ab | 2.87±0.08Ba | 0.15±0.01Bb | ND | 8.90±0.57Ba |

| LP | 4.07±0.03Bc | 10.03±0.94Ba | 3.18±0.18Ba | ND | 0.06±0.05Ba | 7.38±0.31Bb | |

| L0 | 4.30±0.02Bb | 10.10±0.66Aa | 2.51±0.96Ba | 0.30±0.05Ba | ND | 7.90±0.06Bb | |

| A5 | LB | 5.14±0.01Ac | 1.09±0.04Cc | 4.02±0.05Ab | 1.72±0.09Aa | 0.05±0.03Aa | 15.62±0.32Aa |

| LP | 5.25±0.01Aa | 1.59±0.03Ca | 3.91±0.03Ab | 1.91±0.34Aa | 0.01±0.01Aa | 12.52±0.15Ac | |

| L0 | 5.20±0.01Ab | 1.31±0.11Cb | 4.34±0.17Aa | 1.79±0.10Aa | 0.12±0.01Aa | 13.62±0.33Ab |

表4 全株玉米-大豆混合青贮发酵品质

Table 4 Fermentation quality of whole maize-soybean mixed silage

混合比例 Mixing ratio | 乳酸菌剂 Lactic acid bacteria agent | pH值 pH value | 乳酸 Lactic acid (%DM) | 乙酸 Acetic acid (%DM) | 丙酸 Propionic acid (%DM) | 丁酸 Butyric acid (%DM) | 氨态氮/总氮 Ammonia-N/ total-N (%) |

|---|---|---|---|---|---|---|---|

| A1 | LB | 4.01±0.00Ea | 5.02±0.41Ac | 2.61±0.94Ba | ND | 0.03±0.02Aa | 8.65±0.31Ba |

| LP | 3.60±0.01Ec | 10.42±0.14Ba | 0.39±0.01Db | 0.21±0.01Cb | ND | 4.63±0.41Cb | |

| L0 | 3.75±0.01Eb | 7.56±0.30Bb | 1.04±0.28Cb | 0.39±0.01Ba | ND | 4.72±0.31Cb | |

| A2 | LB | 4.27±0.00Da | 3.22±0.47Bc | 3.17±0.51ABa | 0.14±0.02Ba | ND | 8.40±0.15Ba |

| LP | 3.79±0.01Dc | 14.94±1.18Aa | 0.52±0.04Db | 0.15±0.11Ca | ND | 4.62±0.34Cb | |

| L0 | 3.93±0.01Db | 9.97±0.57Ab | 1.28±0.35Cb | 0.30±0.01Ba | ND | 5.24±0.55Cb | |

| A3 | LB | 4.40±0.00Ca | 4.83±0.60ABc | 2.83±0.21Ba | 0.14±0.01Bb | ND | 8.42±0.62Ba |

| LP | 3.91±0.02Cc | 14.60±6.88Aa | 0.78±0.04Cc | 1.26±0.22Ba | ND | 6.87±0.15Ba | |

| L0 | 4.07±0.01Cb | 10.31±0.51Ab | 2.39±0.08Bb | 0.29±0.02Bab | ND | 7.07±0.93Ba | |

| A4 | LB | 4.50±0.02Ba | 5.32±1.44Ab | 2.87±0.08Ba | 0.15±0.01Bb | ND | 8.90±0.57Ba |

| LP | 4.07±0.03Bc | 10.03±0.94Ba | 3.18±0.18Ba | ND | 0.06±0.05Ba | 7.38±0.31Bb | |

| L0 | 4.30±0.02Bb | 10.10±0.66Aa | 2.51±0.96Ba | 0.30±0.05Ba | ND | 7.90±0.06Bb | |

| A5 | LB | 5.14±0.01Ac | 1.09±0.04Cc | 4.02±0.05Ab | 1.72±0.09Aa | 0.05±0.03Aa | 15.62±0.32Aa |

| LP | 5.25±0.01Aa | 1.59±0.03Ca | 3.91±0.03Ab | 1.91±0.34Aa | 0.01±0.01Aa | 12.52±0.15Ac | |

| L0 | 5.20±0.01Ab | 1.31±0.11Cb | 4.34±0.17Aa | 1.79±0.10Aa | 0.12±0.01Aa | 13.62±0.33Ab |

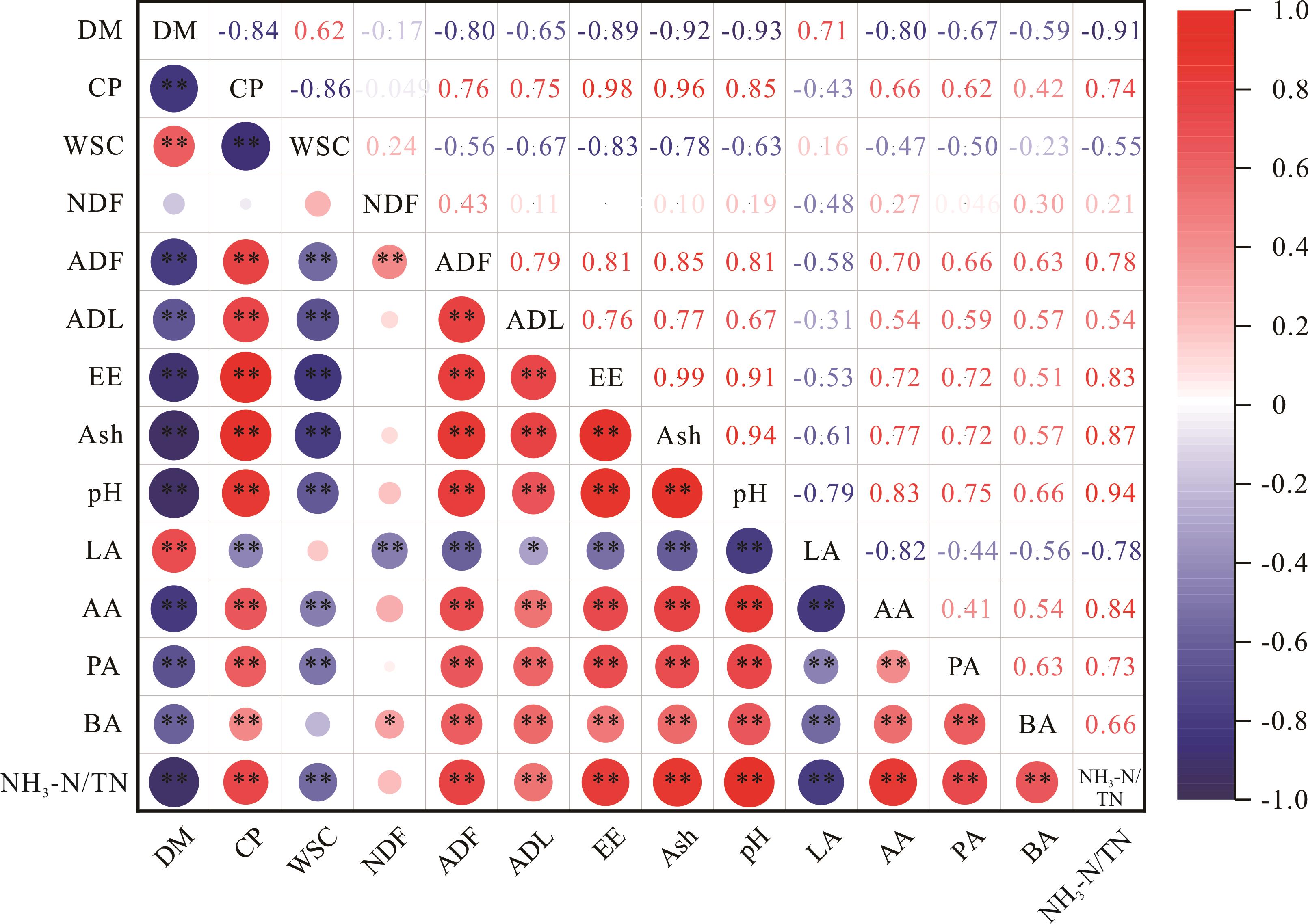

图3 全株玉米-大豆青贮营养品质与发酵品质相关性分析*表示在0.05水平上显著相关(P<0.05),**表示在0.01水平上极显著相关(P<0.01);红色圆圈表示正相关(0<r<1),蓝色圆圈表示负相关(-1<r<0);DM:干物质,CP:粗蛋白,WSC:可溶性碳水化合物,NDF:中性洗涤纤维,ADF:酸性洗涤纤维,ADL:酸性洗涤木质素,EE:粗脂肪,Ash:粗灰分,LA:乳酸,AA:乙酸,PA:丙酸,BA:丁酸,NH3-N/TN:氨态氮/总氮。* indicates a significant correlation at the 0.05 level (P<0.05), ** indicates a very significant correlation at the 0.01 level (P<0.01);The red circles represent positive correlations (0<r<1),while the blue circles represent negative correlations (-1<r<0);DM:Dry matter,CP:Crude protein,WSC:Water soluble carbohydrate,NDF:Neutral detergent fiber,ADF:Acid detergent fiber,ADL:Acid detergent lignin,EE:Ether extract,Ash:Crude ash,LA:Lactic acid,AA:Acetic acid,PA:Propionic acid,BA:Butyric acid,NH3-N/TN:Ammonia-N/total-N.

Fig.3 Correlation analysis between the nutrient quality and fermentation quality of whole maize-soybean silage

混合比例 Mixing ratio | 乳酸菌剂 Lactic acid bacteria agent | 加权关联度 Weighted correlation degree | 加权排名 Weighted ranking |

|---|---|---|---|

| A1 | LB | 0.595 | 10 |

| LP | 0.649 | 3 | |

| L0 | 0.555 | 12 | |

| A2 | LB | 0.618 | 8 |

| LP | 0.683 | 1 | |

| L0 | 0.570 | 11 | |

| A3 | LB | 0.670 | 2 |

| LP | 0.632 | 4 | |

| L0 | 0.631 | 5 | |

| A4 | LB | 0.597 | 9 |

| LP | 0.621 | 7 | |

| L0 | 0.625 | 6 | |

| A5 | LB | 0.516 | 15 |

| LP | 0.540 | 13 | |

| L0 | 0.521 | 14 |

表5 不同混合比例和乳酸菌添加剂组的关联度及排名

Table 5 Correlation and ranking of different mixing ratios and lactic acid bacteria additive groups

混合比例 Mixing ratio | 乳酸菌剂 Lactic acid bacteria agent | 加权关联度 Weighted correlation degree | 加权排名 Weighted ranking |

|---|---|---|---|

| A1 | LB | 0.595 | 10 |

| LP | 0.649 | 3 | |

| L0 | 0.555 | 12 | |

| A2 | LB | 0.618 | 8 |

| LP | 0.683 | 1 | |

| L0 | 0.570 | 11 | |

| A3 | LB | 0.670 | 2 |

| LP | 0.632 | 4 | |

| L0 | 0.631 | 5 | |

| A4 | LB | 0.597 | 9 |

| LP | 0.621 | 7 | |

| L0 | 0.625 | 6 | |

| A5 | LB | 0.516 | 15 |

| LP | 0.540 | 13 | |

| L0 | 0.521 | 14 |

| 1 | Duan J X. Construction of silage maize and amaranth planting patterns and quality evaluation of mixed forage. Kunming: Yunnan Agricultural University, 2023. |

| 段佳鑫. 青贮玉米和籽粒苋种植模式构建及混贮饲草品质评价. 昆明: 云南农业大学, 2023. | |

| 2 | Zeng T R, Wu Y S, Xin Y F, et al. Silage quality and output of different maize-soybean strip intercropping patterns. Fermentation, 2022, 8(4): 174. |

| 3 | Fu L D, Ji L Z, Fan H. Yield and benefit analysis of different soybean varieties under the combined planting model of soybean and maize strip. Modern Agricultural Science and Technology, 2023(23): 21-23. |

| 付立冬, 季林章, 范辉. 大豆玉米带状复合种植模式下不同大豆品种产量及效益分析. 现代农业科技, 2023(23): 21-23. | |

| 4 | Yuan X T, Wang T, Luo K, et al. Effects of bandwidth and plant spacing on biomass accumulation and allocation and yield formation in strip intercropping soybean. Acta Agronomica Sinica, 2024, 50(1): 161-171. |

| 袁晓婷, 王甜, 罗凯, 等. 带宽和株距对带状间作大豆物质积累分配及产量形成的影响. 作物学报, 2024, 50(1): 161-171. | |

| 5 | Gao C, Chen P, Du Q, et al. Effects of sowing date and density on stem, leaf growth, and yield formation in strip intercropping soybean. Acta Agronomica Sinica, 2023, 49(11): 3090-3099. |

| 高超, 陈平, 杜青, 等. 播期、密度对带状间作大豆茎叶生长及产量形成的影响. 作物学报, 2023, 49(11): 3090-3099. | |

| 6 | Sui H M J L. Effects of different mixing ratios on silage quality, aerobic stability, microbial diversity and rumen degradation characteristics of whole plant corn with whole plant soybean. Tongliao: Inner Mongolia Minzu University, 2023. |

| 隋胡木吉勒. 不同混合比例对全株玉米与全株大豆混合青贮品质、有氧稳定性、微生物多样性及瘤胃降解特性的影响. 通辽: 内蒙古民族大学, 2023. | |

| 7 | Li R R, Zheng M H, Cui X Y, et al. Screening of lactic acid bacteria and its effect on fermentation characteristics of alfalfa silage. Chinese Journal of Grassland, 2021, 43(11): 69-75, 104. |

| 李荣荣, 郑猛虎, 崔欣雨, 等. 优良乳酸菌的筛选及对苜蓿青贮发酵品质的影响. 中国草地学报, 2021, 43(11): 69-75, 104. | |

| 8 | Xu D M, Ding W R, Ke W C, et al. Modulation of metabolome and bacterial community in whole crop corn silage by inoculating homofermentative Lactobacillus plantarum and heterofermentative Lactobacillus buchneri. Frontiers in Microbiology, 2018(9): 3299. |

| 9 | Cui B, Wang J T, Zhang X F, et al. Effects of the quality of whole corn silage and its evaluation method. China Feed, 2022(7): 116-121. |

| 崔彪, 王继彤, 张晓峰, 等. 影响全株玉米青贮饲料质量的因素及质量评价方法. 中国饲料, 2022(7): 116-121. | |

| 10 | Thompson S J, Jenny K, Silva L S, et al. Forage mass and nutritive value of grain- and forage-type soybean cultivars managed under different row spacings and clipping heights. Agronomy, 2023, 13(2): 487. |

| 11 | Li X L. Biomass yield and fermentation quality of silage corn and soybean grown in strip intercropping system. Chengdu: Sichuan Agricultural University, 2023. |

| 李小铃. 青贮玉米与大豆带状间作对生物产量及发酵品质的影响. 成都: 四川农业大学, 2023. | |

| 12 | Xiao Z M, Fan X, Ma D X, et al. Determination of crude protein in feed, GB/T 6432-2018. Beijing: China Standard Press, 2018. |

| 肖志明, 樊霞, 马东霞, 等. 饲料中粗蛋白的测定, GB/T 6432-2018. 北京: 中国标准出版社, 2018. | |

| 13 | Thomas T A. An automated procedure for the determination of soluble carbohydrates in herbage. Journal of Food Science, 1977(28): 639-642. |

| 14 | Zhang L Y. Feed analysis and feed quality detection technology. Beijing: China Agriculture University Press, 2007. |

| 张丽英. 饲料分析及饲料质量检测技术. 北京: 中国农业大学出版社, 2007. | |

| 15 | General Administration of Quality Supervosopm, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China. Determination of crude fat in feeds, GB/T 6433-2006. Beijing: Standard Press of China, 2006. |

| 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 饲料中粗脂肪的测定, GB/T 6433-2006. 北京: 中国标准出版社, 2006. | |

| 16 | Wu R X, Yang L, He Y F, et al. Determination of crude ash content in feed, GB/T 6438-2007. Beijing: China Standard Press, 2007. |

| 武润仙, 杨林, 何一帆, 等. 饲料中粗灰分的测定, GB/T 6438-2007. 北京: 中国标准出版社, 2007. | |

| 17 | Xu Q F, Yu Z, Han J G, et al. Determining organic acid in alfalfa silage by HPLC. Grassland and Turf, 2007, 2(17): 63-65, 67. |

| 许庆方, 玉柱, 韩建国, 等. 高效液相色谱法测定紫花苜蓿青贮中的有机酸. 草原与草坪, 2007, 2(17): 63-65, 67. | |

| 18 | Lin L F. Effects of add sorbic acid and ethanol on the fermentation quality of alfalfa and white clover silages. Nanjing: Nanjing Agricultural University, 2013. |

| 林丽芳. 添加山梨酸、乙醇对紫花苜蓿和白三叶发酵品质的影响. 南京: 南京农业大学, 2013. | |

| 19 | Li H P, Guan H, Jia Z F, et al. Screening of antifreeze-thawed lactic acid bacteria and their effects on oat silage fermentation quality and aerobic stability. Acta Prataculturae Sinica, 2022, 31(12): 158-170. |

| 李海萍, 关皓, 贾志锋, 等. 抗冻融乳酸菌的筛选及其对燕麦青贮品质和有氧稳定性的影响. 草业学报, 2022, 31(12): 158-170. | |

| 20 | Meng Y, Tian W Z, Wen P F, et al. Comprehensive evaluation of drought resistance of wheat varieties based on synergy of different developmental stages. Acta Agronomica Sinica, 2023, 49(2): 570-582. |

| 孟雨, 田文仲, 温鹏飞, 等. 基于不同发育阶段协同的小麦品种抗旱性综合评判. 作物学报, 2023, 49(2): 570-582. | |

| 21 | Yan Y H, Li J L, Guo X S, et al. A study on fermentation quality of Italian ryegrass and soybean straw mixed silage. Acta Prataculturae Sinica, 2014, 23(4): 94-99. |

| 闫艳红, 李君临, 郭旭生, 等. 多花黑麦草与大豆秸秆混合青贮发酵品质的研究. 草业学报, 2014, 23(4): 94-99. | |

| 22 | Chen P F, Bai S Q, Yang F Y, et al. Effects of additives and moisture on fermentation quality of smooth vetch silage. Acta Prataculturae Sinica, 2013, 22(2): 80-86. |

| 陈鹏飞, 白史且, 杨富裕, 等. 添加剂和水分对光叶紫花苕青贮品质的影响. 草业学报, 2013, 22(2): 80-86. | |

| 23 | Sa R L. Effects of lactic acid bacteria on fermentation quality, aerobic stability and microbial diversity of whole corn and soybean mixed silage. Tongliao: Inner Mongolia Minzu University, 2023. |

| 萨如拉. 乳酸菌对全株玉米大豆混合青贮发酵品质、有氧稳定性及微生物多样性的影响. 通辽: 内蒙古民族大学, 2023. | |

| 24 | Kung L, Shaver R, Grant R, et al. Silage review: Interpretation of chemical, microbial, and organoleptic components of silages. Journal of Dairy Science, 2018, 101(5): 4020-4033. |

| 25 | Chen Y. Effects of soybean variety and sowing date on yield and quality of mixed silage with soybean-maize strip intercropping. Chengdu: Sichuan Agricultural University, 2023. |

| 陈阳. 大豆品种及播期对大豆玉米带状间作混合青贮产量及品质的影响. 成都: 四川农业大学, 2023. | |

| 26 | Costa A C M, Jara G E S, Orrico M J A, et al. Fermentative parameters and chemical composition of mixed silages from corn-Crotalaria intercropping. Animal Feed Science and Technology, 2023(305): 115779. |

| 27 | Jahanzad E, Sadeghpour A, Hashemi M, et al. Silage fermentation profile, chemical composition and economic evaluation of millet and soya bean grown in monocultures and as intercrops. Grass and Forage Science, 2016, 71(4): 584-594. |

| 28 | Zhan J Q, Chen D D, Guo T X, et al. Effects of different additives on silage quality of Chinese medicinal residue. Acta Agrestia Sinica, 2023, 31(12): 3851-3857. |

| 詹佳琦, 陈丹丹, 郭田心, 等. 不同添加剂对中药渣青贮品质的影响. 草地学报, 2023, 31(12): 3851-3857. | |

| 29 | Parra C, Bolson D, Jacovaci F, et al. Influence of soybean-crop proportion on the conservation of maize-soybean bi-crop silage. Animal Feed Science and Technology, 2019(257): 114295. |

| 30 | Zeng T, Li X L, Guan H, et al. Dynamic microbial diversity and fermentation quality of the mixed silage of corn and soybean grown in strip intercropping system. Bioresource Technology, 2020(313): 123655. |

| 31 | Nascimento C M A, Gomes O P, Paula V S D, et al. Fermentative profile and lactic acid bacterial dynamics in non-wilted and wilted alfalfa silage in tropical conditions. Molecular Biology Reports, 2018, 46(1): 451-460. |

| 32 | Muck R E, Nadeau E M G, McAllister T A, et al. Silage review: Recent advances and future uses of silage additives. Journal of Dairy Science, 2018, 101(5): 3980-4000. |

| 33 | Bai J, Ding Z T, Su R N, et al. Storage temperature is more effective than lactic acid bacteria inoculations in manipulating fermentation and bacterial community diversity, co-occurrence and functionality of the whole-plant corn silage. Microbiology Spectrum, 2022, 10(2): 10122. |

| 34 | Xu J Z, Ma J F, Sa R L, et al. Effects of lactic acid bacteria inoculants on the nutrient composition, fermentation quality, and microbial diversity of whole-plant soybean-corn mixed silage. Frontiers in Microbiology, 2024(15): 1347293. |

| 35 | Érica S D B, Martinele D C, Mauro E S, et al. The effects of Lactobacillus hilgardii 4785 and Lactobacillus buchneri 40788 on the microbiome, fermentation, and aerobic stability of corn silage ensiled for various times. Journal of Dairy Science, 2021, 104(10): 10678-10698. |

| 36 | Jonas J, Vilma V, Rafael C D A, et al. Influence of ensiling timing and inoculation on whole plant maize silagefermentation and aerobic stability (preliminary research). Plants, 2024, 13(20): 2894. |

| [1] | 王思然, 丁成龙, 田吉鹏, 程云辉, 许能祥, 张文洁, 王欣, 刘蓓一. 乳酸菌和抗真菌添加剂对湿啤酒糟全混合日粮青贮发酵品质、体外消化率及有氧稳定性的影响[J]. 草业学报, 2025, 34(6): 213-226. |

| [2] | 王思然, 刘蓓一, 田吉鹏, 程云辉, 许能祥, 张文洁, 王欣, 丁成龙. 复合乳酸菌添加剂对低温环境下意大利黑麦草青贮发酵品质的影响[J]. 草业学报, 2025, 34(5): 159-170. |

| [3] | 梁宇成, 张晓雯, 邵涛, 王文博, 原现军. 乳酸菌对全株玉米青贮发酵品质和霉菌毒素含量的影响[J]. 草业学报, 2025, 34(3): 123-133. |

| [4] | 唐璎, 刘晓静, 赵雅姣, 董霖. 甘肃不同区域青贮紫花苜蓿乳酸菌群落特征及其驱动因子研究[J]. 草业学报, 2024, 33(2): 112-124. |

| [5] | 黄丽娟, 孙镕基, 高文婧, 张志飞, 陈桂华. 全株水稻表面优势乳酸菌的筛选与鉴定[J]. 草业学报, 2024, 33(1): 117-125. |

| [6] | 田静, 曹彩霞, 黄莉莹, 吴娟燕, 张建国. 耐低营养乳酸菌筛选及对难青贮牧草发酵品质的影响[J]. 草业学报, 2023, 32(9): 222-230. |

| [7] | 田吉鹏, 刘蓓一, 顾洪如, 丁成龙, 程云辉, 玉柱. 乳酸菌及丙酸钙对全株玉米和燕麦青贮饲料发酵品质和霉菌毒素含量的影响[J]. 草业学报, 2022, 31(8): 157-166. |

| [8] | 蔺豆豆, 琚泽亮, 柴继宽, 赵桂琴. 青藏高原燕麦附着耐低温乳酸菌的筛选与鉴定[J]. 草业学报, 2022, 31(5): 103-114. |

| [9] | 杨德智, 王晨, 侯明杰, 王虎成. 饲用甜高粱和全株玉米青贮对肉羊前胃微生态的影响[J]. 草业学报, 2022, 31(4): 145-154. |

| [10] | 李海萍, 关皓, 贾志锋, 刘文辉, 马祥, 刘勇, 汪辉, 马力, 周青平. 抗冻融乳酸菌的筛选及其对燕麦青贮品质和有氧稳定性的影响[J]. 草业学报, 2022, 31(12): 158-170. |

| [11] | 王挺, 宋磊, 王旭哲, 马春晖, 杜保军, 张凡凡. 复合乳酸菌对番茄皮渣与苜蓿混合青贮发酵品质及瘤胃降解率的影响[J]. 草业学报, 2022, 31(10): 167-177. |

| [12] | 温媛媛, 张美琦, 刘桃桃, 沈宜钊, 高艳霞, 李秋凤, 曹玉凤, 李建国. 体外产气法评价生薯条加工副产品-稻草混贮与全株玉米青贮组合效应的研究[J]. 草业学报, 2021, 30(8): 154-163. |

| [13] | 张丹丹, 张元庆, 程景, 靳光, 李博, 王栋才, 徐芳, 孙锐锋. 不同粗饲料组合对晋南牛瘤胃体外发酵特性的研究[J]. 草业学报, 2021, 30(7): 93-100. |

| [14] | 黄丽琴, 李松桥, 袁振中, 唐晶, 闫景彩, 唐启源. 全株水稻与平菇菌糠共发酵料对浏阳黑山羊屠宰性能、肉品质和器官指数的影响[J]. 草业学报, 2021, 30(6): 133-140. |

| [15] | 余肖飞, 郭晓农, 张妍, 刘子威, 张喜闻, 徐可新, 吴治勇. 响应面法优化藜麦秸秆饲料发酵工艺的研究[J]. 草业学报, 2021, 30(5): 155-164. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||