ISSN 1004-5759 CN 62-1105/S

草业学报 ›› 2022, Vol. 31 ›› Issue (4): 124-135.DOI: 10.11686/cyxb2021035

• 研究论文 • 上一篇

周迪1( ), 杨帅1, 张欣欣1, 袁婧1, 高艳霞2, 李建国2, 汪波3, 周广生3, 傅廷栋3, 叶俊4, 杨利国1,5(

), 杨帅1, 张欣欣1, 袁婧1, 高艳霞2, 李建国2, 汪波3, 周广生3, 傅廷栋3, 叶俊4, 杨利国1,5( ), 滑国华1,5(

), 滑国华1,5( )

)

收稿日期:2021-01-26

修回日期:2021-03-22

出版日期:2022-04-20

发布日期:2022-01-25

通讯作者:

杨利国,滑国华

作者简介:huaguohua@mail.hzau.edu.cn基金资助:

Di ZHOU1( ), Shuai YANG1, Xin-xin ZHANG1, Jing YUAN1, Yan-xia GAO2, Jian-guo LI2, Bo WANG3, Guang-sheng ZHOU3, Ting-dong FU3, Jun YE4, Li-guo YANG1,5(

), Shuai YANG1, Xin-xin ZHANG1, Jing YUAN1, Yan-xia GAO2, Jian-guo LI2, Bo WANG3, Guang-sheng ZHOU3, Ting-dong FU3, Jun YE4, Li-guo YANG1,5( ), Guo-hua HUA1,5(

), Guo-hua HUA1,5( )

)

Received:2021-01-26

Revised:2021-03-22

Online:2022-04-20

Published:2022-01-25

Contact:

Li-guo YANG,Guo-hua HUA

摘要:

本研究旨在建立一种高效全株油菜青贮的方法。油菜在终花期刈割,就地晾晒3~4 d,水分降至70%以下后,利用不同添加剂方案进行青贮,从感官指标、化学成分和动物瘤胃降解率3个方面,综合评估了7种青贮添加剂(对照组、固体菌剂S组、液体菌剂L组、固体菌剂+液体菌剂SL组、固体菌剂+液体菌剂+玉米粉SLC组、固体菌剂+液体菌剂+红糖SLB组和玉米粉C组)的青贮效果。研究结果表明,各处理组和对照组青贮油菜感官评价指标均为优等,SLC和SLB组pH和水分在各青贮时期最稳定(P<0.05);化学组分分析结果表明SLC组中性洗涤纤维和酸性洗涤纤维含量最低,干物质含量显著高于其他组(P<0.05)。青贮料瘤胃降解(尼龙袋法)试验表明,各组干物质、粗蛋白、中性和酸性洗涤纤维降解率随瘤胃消化时间的增加而提高(P<0.05),油菜青贮60 d时各组间瘤胃内干物质、粗蛋白、中性和酸性洗涤纤维降解率差异显著(P<0.05),其中SLC组在瘤胃(72 h)的降解率最高(P<0.05)。综上所述,全株油菜经刈割晾晒水分降至70%以下后,添加固体菌剂、液体菌剂和玉米粉进行青贮,能有效保存油菜营养价值并提高其瘤胃降解率。本研究为油菜青贮保存提供了技术支撑,对解决养牛业饲料资源短缺、促进“油改饲”工作进程具有重要意义。

周迪, 杨帅, 张欣欣, 袁婧, 高艳霞, 李建国, 汪波, 周广生, 傅廷栋, 叶俊, 杨利国, 滑国华. 添加剂种类和组合对晾晒后全株油菜青贮效果的影响[J]. 草业学报, 2022, 31(4): 124-135.

Di ZHOU, Shuai YANG, Xin-xin ZHANG, Jing YUAN, Yan-xia GAO, Jian-guo LI, Bo WANG, Guang-sheng ZHOU, Ting-dong FU, Jun YE, Li-guo YANG, Guo-hua HUA. Effects of additive types and combinations on silage quality of whole-plant rape after harvesting and air-drying[J]. Acta Prataculturae Sinica, 2022, 31(4): 124-135.

| 项目Item | D | S | L | SL | SLB | SLC | C |

|---|---|---|---|---|---|---|---|

| 玉米粉Corn (g) | - | - | - | - | - | 300 | 300 |

| 固体青贮菌剂 Solid bacterial agent (g) | - | 0.75 | - | 0.75 | 0.75 | 0.75 | - |

| 液体青贮菌剂 Liquid bacterial agent (mL) | - | - | 7.5 | 7.5 | 7.5 | 7.5 | - |

| 红糖 Brown sugar (g) | - | - | - | - | 120 | - | - |

| 水Water* (mL) | - | 60 | 60 | 60 | 60 | 60 | 60 |

表1 油菜青贮试验设计

Table 1 Experimental design of rape silage

| 项目Item | D | S | L | SL | SLB | SLC | C |

|---|---|---|---|---|---|---|---|

| 玉米粉Corn (g) | - | - | - | - | - | 300 | 300 |

| 固体青贮菌剂 Solid bacterial agent (g) | - | 0.75 | - | 0.75 | 0.75 | 0.75 | - |

| 液体青贮菌剂 Liquid bacterial agent (mL) | - | - | 7.5 | 7.5 | 7.5 | 7.5 | - |

| 红糖 Brown sugar (g) | - | - | - | - | 120 | - | - |

| 水Water* (mL) | - | 60 | 60 | 60 | 60 | 60 | 60 |

项目 Item | 评定标准 Evaluation standards | 分值 Score |

|---|---|---|

色泽 Color | 变色严重,呈墨绿色或黄色Serious discoloration, dark green or yellow | 0 |

| 略有色变,呈淡黄色或褐色 Slight color change, light yellow or brown | 1 | |

| 接近原料原色,烘干后呈淡褐色 Close to the original color of the raw material, light brown after drying | 2 | |

气味 Smell | 有很强的丁酸味或氨味,或几乎无酸味 Strong butyric acid or ammonia taste, or almost no sour taste | 2 |

| 丁酸味浓,或有刺鼻的焦糊臭味或霉味 Butyric acid taste strong, or has a pungent burnt smell or musty smell | 4 | |

| 有微弱的丁酸臭味,或较强的酸味,芳香味弱 Weak butyric odor, or a strong sour taste, weak aromatic taste | 10 | |

| 无丁酸臭味,芳香味浓或有明显的面包香味 No butyric odor, strong aroma or obvious bread aroma | 14 | |

质地 Texture | 茎叶腐烂或污染严重 The stems and leaves are rotted or heavily polluted | 0 |

| 茎叶结构保持极差,或发现轻度霉菌污染 The stem and leaf structure remains extremely poor, or mild mold contamination is found | 1 | |

| 茎叶结构破坏不严重 The damage of stem and leaf structure is not serious | 2 | |

| 茎叶结构清晰可见 Stem and leaf structure is clearly visible | 4 | |

等级 Grade | 1级优等Level 1 for excellent | 16~20 |

| 2级尚好Level 2 for good | 10~15 | |

| 3级中等Level 3 for medium | 5~9 | |

| 4级腐败Level 4 for corruption | 0~4 |

表2 青贮饲料感官评价标准

Table 2 Sensory evaluation standard for silage

项目 Item | 评定标准 Evaluation standards | 分值 Score |

|---|---|---|

色泽 Color | 变色严重,呈墨绿色或黄色Serious discoloration, dark green or yellow | 0 |

| 略有色变,呈淡黄色或褐色 Slight color change, light yellow or brown | 1 | |

| 接近原料原色,烘干后呈淡褐色 Close to the original color of the raw material, light brown after drying | 2 | |

气味 Smell | 有很强的丁酸味或氨味,或几乎无酸味 Strong butyric acid or ammonia taste, or almost no sour taste | 2 |

| 丁酸味浓,或有刺鼻的焦糊臭味或霉味 Butyric acid taste strong, or has a pungent burnt smell or musty smell | 4 | |

| 有微弱的丁酸臭味,或较强的酸味,芳香味弱 Weak butyric odor, or a strong sour taste, weak aromatic taste | 10 | |

| 无丁酸臭味,芳香味浓或有明显的面包香味 No butyric odor, strong aroma or obvious bread aroma | 14 | |

质地 Texture | 茎叶腐烂或污染严重 The stems and leaves are rotted or heavily polluted | 0 |

| 茎叶结构保持极差,或发现轻度霉菌污染 The stem and leaf structure remains extremely poor, or mild mold contamination is found | 1 | |

| 茎叶结构破坏不严重 The damage of stem and leaf structure is not serious | 2 | |

| 茎叶结构清晰可见 Stem and leaf structure is clearly visible | 4 | |

等级 Grade | 1级优等Level 1 for excellent | 16~20 |

| 2级尚好Level 2 for good | 10~15 | |

| 3级中等Level 3 for medium | 5~9 | |

| 4级腐败Level 4 for corruption | 0~4 |

时间 Time | 项目 Item | D | S | L | SL | SLB | SLC | C |

|---|---|---|---|---|---|---|---|---|

| 30 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 12.7 | 12.7 | 12.7 | 12.7 | 13.7 | 13.7 | 12.3 | |

| 质地Texture | 3.0 | 3.3 | 3.3 | 3.3 | 3.7 | 3.7 | 3.3 | |

| 综合评分Comprehensive score | 17.7 | 18.0 | 18.0 | 18.0 | 19.4 | 19.4 | 17.6 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 45 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 13.0 | 12.7 | 12.7 | 12.7 | 13.3 | 13.7 | 12.7 | |

| 质地Texture | 3.0 | 3.3 | 3.3 | 3.3 | 3.7 | 3.7 | 3.0 | |

| 综合评分Comprehensive score | 18.0 | 18.0 | 18.0 | 18.0 | 19.0 | 19.4 | 17.7 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 60 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 13.0 | 13.0 | 13.0 | 13.0 | 13.7 | 13.3 | 13.0 | |

| 质地Texture | 3.3 | 3.3 | 3.3 | 3.3 | 3.7 | 3.7 | 3.3 | |

| 综合评分Comprehensive score | 18.3 | 18.3 | 18.3 | 18.3 | 19.4 | 19.0 | 18.3 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 75 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 12.7 | 12.7 | 12.7 | 12.7 | 13.0 | 12.7 | 12.7 | |

| 质地Texture | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.3 | 3.0 | |

| 综合评分Comprehensive score | 17.7 | 17.7 | 17.7 | 17.7 | 18.0 | 18.0 | 17.7 | |

| 等级Level | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 90 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 12.7 | 12.7 | 12.7 | 13.0 | 13.0 | 13.0 | 12.7 | |

| 质地Texture | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| 综合评分Comprehensive score | 17.7 | 17.7 | 17.7 | 18.0 | 18.0 | 18.0 | 17.7 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent |

表3 不同处理组青贮油菜的感官综合评分

Table 3 Comprehensive sensory evaluation of various treated rape silage after ensiling

时间 Time | 项目 Item | D | S | L | SL | SLB | SLC | C |

|---|---|---|---|---|---|---|---|---|

| 30 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 12.7 | 12.7 | 12.7 | 12.7 | 13.7 | 13.7 | 12.3 | |

| 质地Texture | 3.0 | 3.3 | 3.3 | 3.3 | 3.7 | 3.7 | 3.3 | |

| 综合评分Comprehensive score | 17.7 | 18.0 | 18.0 | 18.0 | 19.4 | 19.4 | 17.6 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 45 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 13.0 | 12.7 | 12.7 | 12.7 | 13.3 | 13.7 | 12.7 | |

| 质地Texture | 3.0 | 3.3 | 3.3 | 3.3 | 3.7 | 3.7 | 3.0 | |

| 综合评分Comprehensive score | 18.0 | 18.0 | 18.0 | 18.0 | 19.0 | 19.4 | 17.7 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 60 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 13.0 | 13.0 | 13.0 | 13.0 | 13.7 | 13.3 | 13.0 | |

| 质地Texture | 3.3 | 3.3 | 3.3 | 3.3 | 3.7 | 3.7 | 3.3 | |

| 综合评分Comprehensive score | 18.3 | 18.3 | 18.3 | 18.3 | 19.4 | 19.0 | 18.3 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 75 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 12.7 | 12.7 | 12.7 | 12.7 | 13.0 | 12.7 | 12.7 | |

| 质地Texture | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.3 | 3.0 | |

| 综合评分Comprehensive score | 17.7 | 17.7 | 17.7 | 17.7 | 18.0 | 18.0 | 17.7 | |

| 等级Level | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | |

| 90 d | 颜色Color | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 气味Smell | 12.7 | 12.7 | 12.7 | 13.0 | 13.0 | 13.0 | 12.7 | |

| 质地Texture | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| 综合评分Comprehensive score | 17.7 | 17.7 | 17.7 | 18.0 | 18.0 | 18.0 | 17.7 | |

| 等级Grade | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent | 优等 Excellent |

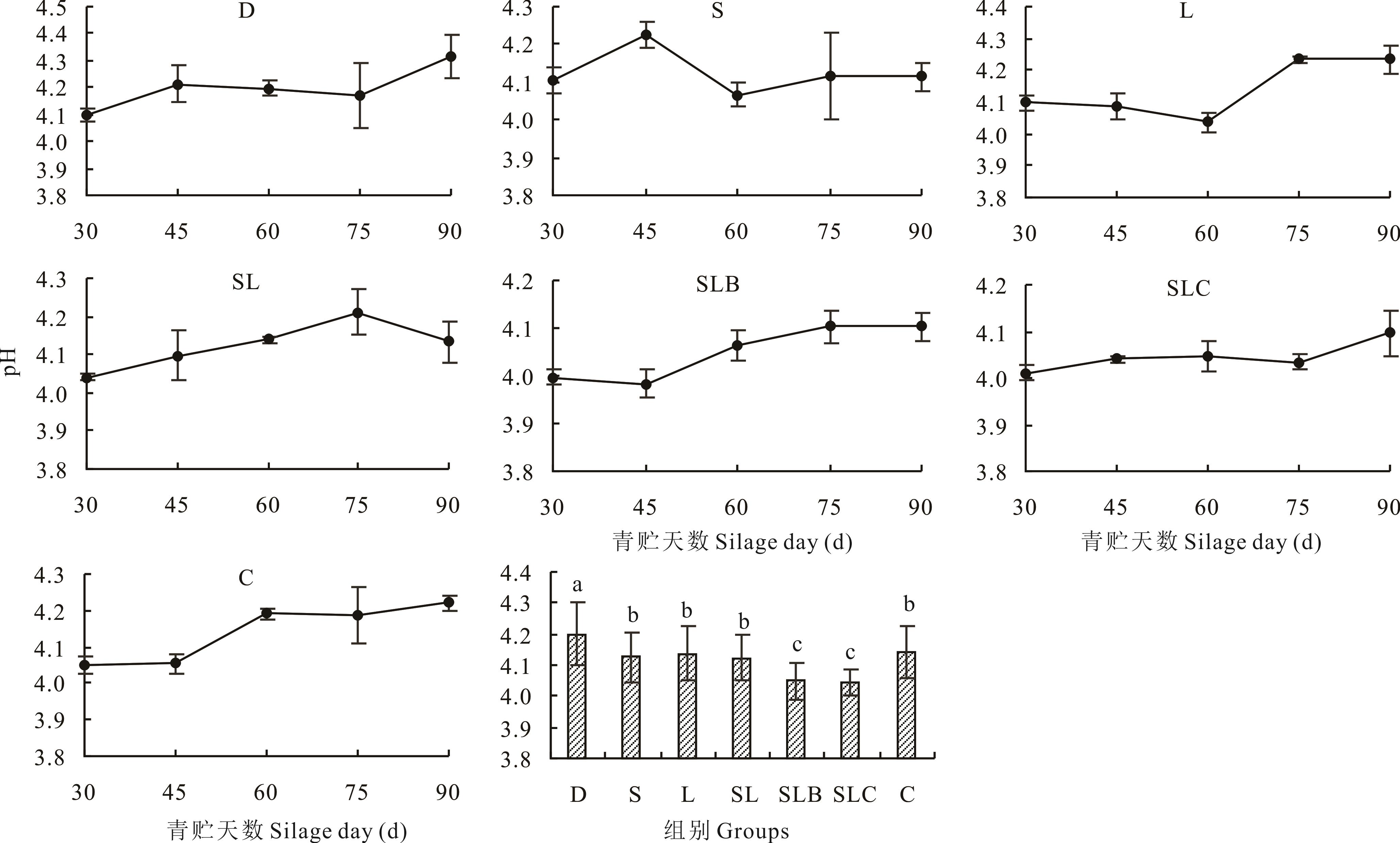

图2 各处理油菜青贮在不同时期的pH值不同小写字母表示各处理组间差异显著(P<0.05),相同字母表示差异不显著,下同。Different lowercase letters indicate significant difference between different treatment groups (P<0.05), the same letters indicate no significant differences, the same below.

Fig.2 The pH value of various treated rape silage in different periods

项目 Item | 青贮时间 Silage time (d) | 含量Content | 标准误SEM | P值P value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | S | L | SL | SLB | SLC | C | 平均 Mean | 时间 Time | 处理 Treatment | 时间×处理Time×treatment | |||

| 干物质DM (g·kg-1) | 30 | 294.2d | 299.8cd | 305.2cd | 330.3ab | 321.4bc | 346.0a | 352.6a | 321.4x | 2.554 | 0.177 | <0.001 | 0.005 |

| 60 | 322.2ab | 329.5ab | 322.5ab | 318.4ab | 316.0b | 338.0a | 338.1a | 326.4x | |||||

| 平均值Mean | 308.2C | 314.6BC | 313.8BC | 324.4B | 318.7BC | 342.0A | 345.4A | ||||||

| 标准误SEM | 4.778 | ||||||||||||

| 粗蛋白CP (%) | 30 | 8.58e | 8.80d | 8.89cd | 9.03b | 8.87cd | 8.91c | 9.24a | 8.91x | 0.008 | <0.001 | <0.001 | <0.001 |

| 60 | 8.90c | 9.09b | 9.42a | 9.40a | 9.03b | 8.88c | 8.59d | 9.05x | |||||

| 平均值Mean | 8.73E | 8.95CD | 9.16B | 9.22A | 8.98C | 8.90D | 8.91D | ||||||

| 标准误SEM | 0.031 | ||||||||||||

水溶性碳 水化合物WSC (g·kg-1 DM ) | 30 | 13.56a | 13.26a | 12.67a | 17.17a | 16.94a | 16.59a | 14.98a | 15.02y | 0.747 | 0.001 | 0.645 | 0.295 |

| 60 | 19.26a | 22.89a | 16.93a | 16.85a | 19.71a | 18.28a | 19.20a | 19.02x | |||||

| 平均值Mean | 16.41A | 18.07A | 14.80A | 17.01A | 18.32A | 17.44A | 17.09A | ||||||

| 标准误SEM | 1.398 | ||||||||||||

| 中性洗涤纤维NDF (g·kg-1 DM) | 30 | 479.4ab | 469.0ab | 463.9b | 480.2ab | 473.6ab | 472.1ab | 480.5a | 474.1x | 1.682 | <0.001 | 0.004 | <0.001 |

| 60 | 487.4a | 480.7a | 474.7ab | 468.0bc | 455.6c | 440.6d | 459.1c | 466.6y | |||||

| 平均值Mean | 483.4A | 474.9A | 469.3A | 474.1A | 464.6A | 456.3A | 469.8A | ||||||

| 标准误SEM | 3.147 | ||||||||||||

| 酸性洗涤纤维ADF (g·kg-1 DM) | 30 | 347.9a | 342.0a | 343.5a | 347.3a | 340.3a | 347.3a | 349.3a | 345.4x | 2.121 | 0.005 | 0.044 | 0.002 |

| 60 | 359.5a | 357.9a | 346.8ab | 335.8bc | 327.8cd | 316.2d | 329.3cd | 339.0x | |||||

| 平均值Mean | 353.7A | 349.9AB | 345.2ABC | 341.5ABCD | 334.1CD | 331.8D | 339.3BCD | ||||||

| 标准误SEM | 3.968 | ||||||||||||

表4 不同处理组青贮油菜在不同时期的化学成分含量

Table 4 The dry matter (DM), crude protein (CP), WSC, neutral detergent fiber (NDF) and acid detergent fiber (ADF) content of various treatment methods of silage rape in different periods

项目 Item | 青贮时间 Silage time (d) | 含量Content | 标准误SEM | P值P value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | S | L | SL | SLB | SLC | C | 平均 Mean | 时间 Time | 处理 Treatment | 时间×处理Time×treatment | |||

| 干物质DM (g·kg-1) | 30 | 294.2d | 299.8cd | 305.2cd | 330.3ab | 321.4bc | 346.0a | 352.6a | 321.4x | 2.554 | 0.177 | <0.001 | 0.005 |

| 60 | 322.2ab | 329.5ab | 322.5ab | 318.4ab | 316.0b | 338.0a | 338.1a | 326.4x | |||||

| 平均值Mean | 308.2C | 314.6BC | 313.8BC | 324.4B | 318.7BC | 342.0A | 345.4A | ||||||

| 标准误SEM | 4.778 | ||||||||||||

| 粗蛋白CP (%) | 30 | 8.58e | 8.80d | 8.89cd | 9.03b | 8.87cd | 8.91c | 9.24a | 8.91x | 0.008 | <0.001 | <0.001 | <0.001 |

| 60 | 8.90c | 9.09b | 9.42a | 9.40a | 9.03b | 8.88c | 8.59d | 9.05x | |||||

| 平均值Mean | 8.73E | 8.95CD | 9.16B | 9.22A | 8.98C | 8.90D | 8.91D | ||||||

| 标准误SEM | 0.031 | ||||||||||||

水溶性碳 水化合物WSC (g·kg-1 DM ) | 30 | 13.56a | 13.26a | 12.67a | 17.17a | 16.94a | 16.59a | 14.98a | 15.02y | 0.747 | 0.001 | 0.645 | 0.295 |

| 60 | 19.26a | 22.89a | 16.93a | 16.85a | 19.71a | 18.28a | 19.20a | 19.02x | |||||

| 平均值Mean | 16.41A | 18.07A | 14.80A | 17.01A | 18.32A | 17.44A | 17.09A | ||||||

| 标准误SEM | 1.398 | ||||||||||||

| 中性洗涤纤维NDF (g·kg-1 DM) | 30 | 479.4ab | 469.0ab | 463.9b | 480.2ab | 473.6ab | 472.1ab | 480.5a | 474.1x | 1.682 | <0.001 | 0.004 | <0.001 |

| 60 | 487.4a | 480.7a | 474.7ab | 468.0bc | 455.6c | 440.6d | 459.1c | 466.6y | |||||

| 平均值Mean | 483.4A | 474.9A | 469.3A | 474.1A | 464.6A | 456.3A | 469.8A | ||||||

| 标准误SEM | 3.147 | ||||||||||||

| 酸性洗涤纤维ADF (g·kg-1 DM) | 30 | 347.9a | 342.0a | 343.5a | 347.3a | 340.3a | 347.3a | 349.3a | 345.4x | 2.121 | 0.005 | 0.044 | 0.002 |

| 60 | 359.5a | 357.9a | 346.8ab | 335.8bc | 327.8cd | 316.2d | 329.3cd | 339.0x | |||||

| 平均值Mean | 353.7A | 349.9AB | 345.2ABC | 341.5ABCD | 334.1CD | 331.8D | 339.3BCD | ||||||

| 标准误SEM | 3.968 | ||||||||||||

项目 Item | 消化时间 Digest time (h) | 降解率Degradation rate (%) | 标准误SEM | P值P value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | S | L | SL | SLB | SLC | C | 平均 Mean | 时间 Time | 处理 Treatment | 时间×处理 Time×treatment | |||

| 干物质DM | 12 | 48.97 | 48.28 | 47.55 | 47.14 | 48.05 | 49.74 | 48.16 | 48.25z | 1.148 | <0.001 | 0.341 | 0.828 |

| 24 | 54.79ab | 52.48ab | 49.03b | 48.28b | 54.14ab | 57.18a | 51.85ab | 52.57y | |||||

| 72 | 61.26 | 63.95 | 61.90 | 62.94 | 65.24 | 61.53 | 63.75 | 62.95x | |||||

| 平均值Mean | 55.01 | 55.05 | 52.50 | 52.79 | 55.26 | 56.15 | 54.58 | ||||||

| 标准误SEM | 1.818 | ||||||||||||

| 粗蛋白CP | 12 | 54.37 | 58.04 | 59.06 | 59.73 | 59.39 | 61.12 | 59.78 | 58.89z | 1.544 | <0.001 | 0.944 | 0.797 |

| 24 | 71.28 | 68.79 | 64.72 | 66.40 | 70.79 | 71.14 | 71.74 | 69.25y | |||||

| 72 | 74.45 | 75.46 | 75.51 | 76.32 | 75.84 | 73.45 | 73.42 | 74.92x | |||||

| 平均值Mean | 66.14 | 67.43 | 66.43 | 67.55 | 68.09 | 68.57 | 68.31 | ||||||

| 标准误SEM | 2.460 | ||||||||||||

| 中性洗涤纤维NDF | 12 | 16.19 | 16.76 | 15.04 | 14.80 | 22.50 | 20.46 | 22.10 | 17.89z | 1.232 | <0.001 | <0.001 | 0.316 |

| 24 | 30.32a | 20.72bcd | 17.89d | 19.14cd | 27.67ab | 25.54abc | 26.44ab | 24.07y | |||||

| 72 | 39.57b | 41.39ab | 39.28b | 40.24ab | 46.39a | 39.98b | 46.59a | 41.91x | |||||

| 平均值Mean | 28.70BC | 26.29C | 25.49C | 24.73C | 32.53AB | 28.66BC | 32.91A | ||||||

| 标准误SEM | 1.850 | ||||||||||||

| 酸性洗涤纤维ADF | 12 | 26.90 | 26.18 | 26.79 | 23.25 | 31.81 | 28.34 | 25.42 | 26.71z | 1.153 | <0.001 | 0.002 | 0.216 |

| 24 | 39.30a | 31.03bcd | 29.09d | 29.46cd | 36.69ab | 36.79ab | 35.28abc | 33.87y | |||||

| 72 | 45.67c | 48.40abc | 47.03bc | 46.89bc | 52.21ab | 48.06abc | 53.01a | 48.84x | |||||

| 平均值Mean | 36.70BC | 35.20BC | 35.10BC | 33.20C | 40.56A | 37.14AB | 37.90AB | ||||||

| 标准误SEM | 1.803 | ||||||||||||

表5 不同处理方式青贮油菜在青贮30 d时的瘤胃体内12、24和72 h的营养成分降解率

Table 5 Degradation rate of nutrient components in rumen for 12, 24 and 72 hours of silage rape under different treatments for 30 days

项目 Item | 消化时间 Digest time (h) | 降解率Degradation rate (%) | 标准误SEM | P值P value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | S | L | SL | SLB | SLC | C | 平均 Mean | 时间 Time | 处理 Treatment | 时间×处理 Time×treatment | |||

| 干物质DM | 12 | 48.97 | 48.28 | 47.55 | 47.14 | 48.05 | 49.74 | 48.16 | 48.25z | 1.148 | <0.001 | 0.341 | 0.828 |

| 24 | 54.79ab | 52.48ab | 49.03b | 48.28b | 54.14ab | 57.18a | 51.85ab | 52.57y | |||||

| 72 | 61.26 | 63.95 | 61.90 | 62.94 | 65.24 | 61.53 | 63.75 | 62.95x | |||||

| 平均值Mean | 55.01 | 55.05 | 52.50 | 52.79 | 55.26 | 56.15 | 54.58 | ||||||

| 标准误SEM | 1.818 | ||||||||||||

| 粗蛋白CP | 12 | 54.37 | 58.04 | 59.06 | 59.73 | 59.39 | 61.12 | 59.78 | 58.89z | 1.544 | <0.001 | 0.944 | 0.797 |

| 24 | 71.28 | 68.79 | 64.72 | 66.40 | 70.79 | 71.14 | 71.74 | 69.25y | |||||

| 72 | 74.45 | 75.46 | 75.51 | 76.32 | 75.84 | 73.45 | 73.42 | 74.92x | |||||

| 平均值Mean | 66.14 | 67.43 | 66.43 | 67.55 | 68.09 | 68.57 | 68.31 | ||||||

| 标准误SEM | 2.460 | ||||||||||||

| 中性洗涤纤维NDF | 12 | 16.19 | 16.76 | 15.04 | 14.80 | 22.50 | 20.46 | 22.10 | 17.89z | 1.232 | <0.001 | <0.001 | 0.316 |

| 24 | 30.32a | 20.72bcd | 17.89d | 19.14cd | 27.67ab | 25.54abc | 26.44ab | 24.07y | |||||

| 72 | 39.57b | 41.39ab | 39.28b | 40.24ab | 46.39a | 39.98b | 46.59a | 41.91x | |||||

| 平均值Mean | 28.70BC | 26.29C | 25.49C | 24.73C | 32.53AB | 28.66BC | 32.91A | ||||||

| 标准误SEM | 1.850 | ||||||||||||

| 酸性洗涤纤维ADF | 12 | 26.90 | 26.18 | 26.79 | 23.25 | 31.81 | 28.34 | 25.42 | 26.71z | 1.153 | <0.001 | 0.002 | 0.216 |

| 24 | 39.30a | 31.03bcd | 29.09d | 29.46cd | 36.69ab | 36.79ab | 35.28abc | 33.87y | |||||

| 72 | 45.67c | 48.40abc | 47.03bc | 46.89bc | 52.21ab | 48.06abc | 53.01a | 48.84x | |||||

| 平均值Mean | 36.70BC | 35.20BC | 35.10BC | 33.20C | 40.56A | 37.14AB | 37.90AB | ||||||

| 标准误SEM | 1.803 | ||||||||||||

项目 Item | 消化时间 Digest time (h) | 降解率Degradation rate (%) | 标准误SEM | P值P value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | S | L | SL | SLB | SLC | C | 平均 Mean | 时间 Time | 处理 Treatment | 时间×处理 Time×treatment | |||

干物质 DM | 12 | 46.74c | 47.82bc | 49.49c | 49.27bc | 50.62bc | 57.61a | 54.06ab | 50.90z | 1.065 | <0.001 | <0.001 | 0.169 |

| 24 | 48.18c | 54.91bc | 56.09b | 56.56b | 65.67a | 67.51a | 57.88b | 58.11y | |||||

| 72 | 62.86d | 63.43d | 66.90cd | 68.66bc | 74.53a | 75.45a | 72.01ab | 69.12x | |||||

| 平均值Mean | 52.94E | 55.39DE | 57.49D | 58.16CD | 63.60B | 66.86A | 61.31BC | ||||||

| 标准误SEM | 1.641 | ||||||||||||

粗蛋白 CP | 12 | 50.59b | 63.35a | 62.65a | 66.10a | 67.10a | 67.71a | 63.86a | 63.59z | 0.954 | <0.001 | <0.001 | 0.049 |

| 24 | 66.73c | 68.45c | 72.64bc | 71.40bc | 77.41ab | 79.97a | 67.75c | 71.33y | |||||

| 72 | 74.36c | 78.05b | 80.31ab | 81.65ab | 83.40a | 83.40a | 80.25ab | 80.35x | |||||

| 平均值Mean | 64.97D | 70.04C | 72.39C | 73.05BC | 75.68AB | 77.26A | 70.20C | ||||||

| 标准误SEM | 1.431 | ||||||||||||

中性洗涤纤维 NDF | 12 | 14.26c | 18.45bc | 17.03bc | 16.73bc | 17.41bc | 27.73a | 24.12ab | 19.33z | 1.487 | <0.001 | <0.001 | 0.155 |

| 24 | 24.62c | 29.92c | 28.94c | 29.61c | 42.33ab | 45.03a | 32.74bc | 33.75y | |||||

| 72 | 42.45cd | 41.38d | 46.23cd | 48.69bc | 56.21a | 56.95a | 53.11ab | 49.46x | |||||

| 平均值Mean | 27.29C | 30.59C | 30.73C | 31.68C | 38.65B | 44.15A | 36.66B | ||||||

| 标准误SEM | 2.369 | ||||||||||||

酸性洗涤纤维 ADF | 12 | 23.74 | 25.42 | 22.40 | 23.53 | 24.87 | 30.90 | 28.61 | 25.53z | 1.344 | <0.001 | <0.001 | 0.262 |

| 24 | 38.74c | 40.58bc | 37.67c | 38.16c | 49.09ab | 51.65a | 40.51bc | 42.62y | |||||

| 72 | 49.77c | 48.98c | 52.58bc | 53.91bc | 61.15a | 62.27a | 58.02ab | 55.37x | |||||

| 平均值Mean | 37.21C | 39.94C | 38.44C | 39.42C | 45.03B | 49.30A | 44.10B | ||||||

| 标准误SEM | 2.135 | ||||||||||||

表6 不同处理方式青贮油菜在青贮60 d时的瘤胃体内12、24和72 h的营养成分降解率

Table 6 Degradation rate of nutrient components in rumen for 12, 24 and 72 hours of silage rape under different treatments for 60 days

项目 Item | 消化时间 Digest time (h) | 降解率Degradation rate (%) | 标准误SEM | P值P value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | S | L | SL | SLB | SLC | C | 平均 Mean | 时间 Time | 处理 Treatment | 时间×处理 Time×treatment | |||

干物质 DM | 12 | 46.74c | 47.82bc | 49.49c | 49.27bc | 50.62bc | 57.61a | 54.06ab | 50.90z | 1.065 | <0.001 | <0.001 | 0.169 |

| 24 | 48.18c | 54.91bc | 56.09b | 56.56b | 65.67a | 67.51a | 57.88b | 58.11y | |||||

| 72 | 62.86d | 63.43d | 66.90cd | 68.66bc | 74.53a | 75.45a | 72.01ab | 69.12x | |||||

| 平均值Mean | 52.94E | 55.39DE | 57.49D | 58.16CD | 63.60B | 66.86A | 61.31BC | ||||||

| 标准误SEM | 1.641 | ||||||||||||

粗蛋白 CP | 12 | 50.59b | 63.35a | 62.65a | 66.10a | 67.10a | 67.71a | 63.86a | 63.59z | 0.954 | <0.001 | <0.001 | 0.049 |

| 24 | 66.73c | 68.45c | 72.64bc | 71.40bc | 77.41ab | 79.97a | 67.75c | 71.33y | |||||

| 72 | 74.36c | 78.05b | 80.31ab | 81.65ab | 83.40a | 83.40a | 80.25ab | 80.35x | |||||

| 平均值Mean | 64.97D | 70.04C | 72.39C | 73.05BC | 75.68AB | 77.26A | 70.20C | ||||||

| 标准误SEM | 1.431 | ||||||||||||

中性洗涤纤维 NDF | 12 | 14.26c | 18.45bc | 17.03bc | 16.73bc | 17.41bc | 27.73a | 24.12ab | 19.33z | 1.487 | <0.001 | <0.001 | 0.155 |

| 24 | 24.62c | 29.92c | 28.94c | 29.61c | 42.33ab | 45.03a | 32.74bc | 33.75y | |||||

| 72 | 42.45cd | 41.38d | 46.23cd | 48.69bc | 56.21a | 56.95a | 53.11ab | 49.46x | |||||

| 平均值Mean | 27.29C | 30.59C | 30.73C | 31.68C | 38.65B | 44.15A | 36.66B | ||||||

| 标准误SEM | 2.369 | ||||||||||||

酸性洗涤纤维 ADF | 12 | 23.74 | 25.42 | 22.40 | 23.53 | 24.87 | 30.90 | 28.61 | 25.53z | 1.344 | <0.001 | <0.001 | 0.262 |

| 24 | 38.74c | 40.58bc | 37.67c | 38.16c | 49.09ab | 51.65a | 40.51bc | 42.62y | |||||

| 72 | 49.77c | 48.98c | 52.58bc | 53.91bc | 61.15a | 62.27a | 58.02ab | 55.37x | |||||

| 平均值Mean | 37.21C | 39.94C | 38.44C | 39.42C | 45.03B | 49.30A | 44.10B | ||||||

| 标准误SEM | 2.135 | ||||||||||||

| 1 | Dong X Y, Tang S Q. Biological characteristics and application of feed Brassica napus L. Animal Agriculture, 2014(7): 9-11. |

| 董小英, 唐胜球. 饲料油菜生物学特性及应用研究进展. 畜牧产业, 2014(7): 9-11. | |

| 2 | Yang Q F, Teng H Y, Niu J L, et al. Studies on nutrient content dynamics and nutritive value of Huaxie 1 forage rape. Acta Prataculturae Sinica, 2003(2): 87-92. |

| 杨祁峰, 滕怀渊, 牛菊兰, 等. 饲用双低油菜华协1号营养成分含量动态及营养价值研究. 草业学报, 2003(2): 87-92. | |

| 3 | Statistics Bureau of the People's Republic of China. China statistical yearbook. Beijing: China Statistics Press, 2019. |

| 中华人民共和国国家统计局. 中国统计年鉴. 北京: 中国统计出版社, 2019. | |

| 4 | Grant R J, Ferraretto L F. Silage review: Silage feeding management: Silage characteristics and dairy cow feeding behavior. Journal of Dairy Science, 2018, 101(5): 4111-4121. |

| 5 | Li D X, Ni K K, Zhang Y C, et al. Influence of lactic acid bacteria, cellulase, cellulase-producing Bacillus pumilus and their combinations on alfalfa silage quality. Journal of Integrative Agriculture, 2018, 17(12): 2768-2782. |

| 6 | Zhao N, Yang X H, Wei J T, et al. Nutritional value and silage fermentation quality of forage cole in different growth periods. Pratacultural Science, 2020, 37(5): 933-941. |

| 赵娜, 杨雪海, 魏金涛, 等. 不同生长期饲用油菜的营养价值和青贮发酵品质. 草业科学, 2020, 37(5): 933-941. | |

| 7 | Yin F T, Zhang Y L, Shi J, et al. Quality of silage made with different ratios of feed rape and corn stalk. Acta Prataculturae Sinica, 2018, 26(4): 1011-1019. |

| 阴法庭, 张玉龙, 石婧, 等. 饲料油菜与玉米秸秆混合青贮品质研究. 草业学报, 2018, 26(4): 1011-1019. | |

| 8 | Wang H Z, Shang Z D, Liu S Z, et al. Effect of different ratios of rape and clover on mixed silage fermentation quality in tibet. Journal of Plateau Agriculture, 2018, 2(6): 647-653. |

| 王洪壮, 商振达, 刘锁珠, 等. 西藏地区不同比例油菜与三叶草混合青贮对饲料发酵品质的影响. 高原农业, 2018, 2(6): 647-653. | |

| 9 | Liu Y P, Huang B Z, Liu J Y, et al. The research on nutrients value and silage technology of whole rape plant at fruiting stage. Grass-Feeding Livestock, 2017(6): 22-26. |

| 刘彦培, 黄必志, 刘建勇, 等. 结实期全株油菜及油菜秸秆青贮技术研究. 草食家畜, 2017(6): 22-26. | |

| 10 | Chen D, Li S, Zeng N B, et al. Effect of different additives on fermentation quality of silage with different rations of Amaranthus hypochondriacus and rape straw. Journal of Hunan Agricultural University, 2020, 46(1): 113-118. |

| 陈东, 李顺, 曾宁波, 等. 不同添加剂对籽粒苋与油菜秸秆混合青贮品质的影响. 湖南农业大学学报, 2020, 46(1): 113-118. | |

| 11 | Liu Q H, Li X Y, Desta S T, et al. Effects of Lactobacillus plantarum and fibrolytic enzyme on the fermentation quality and invitro digestibility of total mixed rations silage including rape straw. Journal of Integrative Agriculture, 2016, 15(9): 2087-2096. |

| 12 | Li L Z, Liu C J, Qu M R, et al. Characteristics of a recombinant Lentinula edodes endoglucanase and its potential for application in silage of rape straw. International Journal of Biological Macromolecules, 2019, 139: 49-56. |

| 13 | Mao X, Zhao J Y, Liu G Q, et al. Effect of forage rape fermentation total mixed ration (FTMR) on intensity finishing in lamb. China Feed, 2019(11): 66-68. |

| 毛鑫, 赵家宇, 刘桂琼, 等. 饲料油菜FTMR的羔羊强度育肥效果研究. 中国饲料, 2019(11): 66-68. | |

| 14 | Fan H R. The nutrition value of rape silage and microbial-treated chaff of Flammulina velutipes and feeding effect in buffaloes. Wuhan: Huazhong Agricultural University, 2016. |

| 范海瑞. 青贮油菜与微贮金针菇菌糠的营养价值评定及饲喂奶水牛效果. 武汉: 华中农业大学, 2016. | |

| 15 | Wang L J. Nutrition estimation of drying and silage on the harvested rape and feeding effects of silage rape on diary buffalo. Wuhan: Huazhong Agricultural University, 2017. |

| 王力军. 油菜收割后晾晒和青贮对营养价值的影响与青贮油菜饲喂奶水牛试验研究. 武汉: 华中农业大学, 2017. | |

| 16 | Yang X H, Guo W Z, Huang S W, et al. Study on rape forage nutritive value evaluation in different growth stages. Feed Industry, 2017, 38(21): 19-22. |

| 杨雪海, 郭万正, 黄少文, 等. 不同生长阶段的油菜饲用营养价值评价研究. 饲料工业, 2017, 38(21): 19-22. | |

| 17 | Mcdonald P, Hendson A R. Determination of water-soluble carbohydrates in grass. Journal of the Science of Food and Agriculture, 1964, 15(6): 395-398. |

| 18 | Zhao N,Yang X H,Wei J T, et al. Effects of different carbohydrate sources on quality of forage rape silage. Chinese Journal of Oil Crop Science, 2021, 43(2): 236-240. |

| 赵娜, 杨雪海, 魏金涛, 等. 不同碳水化合物源对饲料油菜青贮品质的影响. 中国油料作物学报, 2021, 43(2): 236-240. | |

| 19 | Wang H C, Liu C L, Liu D S, et al. Evaluation of nutritive value of the forage rape at the different development stages using CNCPS. Feed Industry, 2016, 37(21): 31-34. |

| 王洪超, 刘春龙, 刘大森, 等. 利用CNCPS体系评价不同生育期饲料油菜的营养价值研究. 饲料工业, 2016, 37(21): 31-34. | |

| 20 | Liu Z K, Wang Y F, Wang S P, et al. Drying method effects on forage nutritive quality. Acta Prataculturae Sinica, 2004(3): 47-51. |

| 刘忠宽, 王艳芬, 汪诗平, 等. 不同干燥失水方式对牧草营养品质影响的研究. 草业学报, 2004(3): 47-51. | |

| 21 | Zhu C Y, Huang B, Zhu S S, et al. Discussion on two silage methods of forage rape. Hubei Journal of Animal and Veterinary Sciences, 2019, 40(1): 12-16. |

| 朱昌友, 黄彬, 朱爽爽, 等. 饲料油菜的两种青贮方法探讨. 湖北畜牧兽医, 2019, 40(1): 12-16. | |

| 22 | Ren H W, Wang C, Dou J W, et al. Mixed ensiling quality of maize straw with waste cabbage and biogas production potential analysis. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(12): 187-194. |

| 任海伟, 王聪, 窦俊伟, 等. 玉米秸秆与废弃白菜的混合青贮品质及产沼气能力分析. 农业工程学报, 2016, 32(12): 187-194. | |

| 23 | Li Y F. Effects of mixed silage corn and alfalfa on nutritional value and quality. Xianyang: Northwest A&F University, 2019. |

| 李雅斐. 玉米和紫花苜蓿混合青贮对营养价值和品质的影响. 咸阳: 西北农林科技大学, 2019. | |

| 24 | Qu Y L, Jiang W, Li S L, et al. Study on the evaluation of nutritional value of mixed sowing corn silage and lentil silage. Chinese Journal of Animal Science, 2010, 46(13): 72-74. |

| 曲永利, 蒋微, 李胜利, 等. 青贮玉米与扁豆混播青贮营养价值评定的研究. 中国畜牧杂志, 2010, 46(13): 72-74. | |

| 25 | Santos A O, Ávila C L S , Schwan R F. Selection of tropical lactic acid bacteria for enhancing the quality of maize silage. Journal of Dairy Science, 2013, 96(12): 7777-7789. |

| 26 | Waroon K, Suradej P, David H, et al. Natural lactic acid bacteria population of tropical grasses and their fermentation factor analysis of silage prepared with cellulase and inoculant. Journal of Dairy Science, 2016, 99(12): 9768-9781. |

| 27 | Sun Z H, Liu S M, Tayo G O, et al. Effects of cellulase or lactic acid bacteria on silage fermentation and in vitro gas production of several morphological fractions of maize stover. Animal Feed Science and Technology, 2009, 152(3/4): 219-231. |

| 28 | Zhang J G, Kawamoto H, Cai Y M. Relationships between the addition rates of cellulase or glucose and silage fermentation at different temperatures. Animal Science Journal, 2010, 81(3): 325-330. |

| 29 | Schmidt R J, Kung L .The effects of Lactobacillus buchneri with or without a homolactic bacterium on the fermentation and aerobic stability of corn silages made at different locations. Journal of Dairy Science, 2010, 93(4): 1616-1624. |

| 30 | Chen Y Y, Deng M, Li B, et al. Effects of different additives on the quality of Broussonetia papyrifera silage. Heilongjiang Animal Science and Veterinary Medicine, 2019(14): 120-124. |

| 陈奕业, 邓铭, 李斌, 等. 不同添加剂对构树叶青贮品质的影响. 黑龙江畜牧兽医, 2019(14): 120-124. | |

| 31 | Nagel S A, Broderick G A. Effect of formic acid or formaldehyde treatment of alfalfa silage on nutrient utilization by dairy cows. Journal of Dairy Science, 1992, 75(1): 140-154. |

| 32 | Yu H R, Ge G T, Wang Z J, et al. Effects of formic acid additives and ensiling time on the quality of alfalfa silage. Acta Prataculturae Sinica, 2020, 29(3): 89-95. |

| 于浩然, 格根图, 王志军, 等. 甲酸添加剂及青贮时间对紫花苜蓿青贮品质的影响. 草业学报, 2020, 29(3): 89-95. | |

| 33 | Wang X Z, Yue Y F, Zhang F F, et al. The compaction effect of nutritional quality of whole plant corn silage. Pratacultural Science, 2016, 33(9): 1893-1900. |

| 王旭哲, 岳亚飞, 张凡凡, 等. 全株玉米青贮营养品质的紧实度效应. 草业科学, 2016, 33(9): 1893-1900. | |

| 34 | Xu Y W. Study on effect of three microbial preparations and their conbinations on nutritive value of micro-storage rice straw. Nanchang: Jiangxi Agricultural University, 2012. |

| 许宇薇. 不同微生物制剂及其组合处理对微贮稻草营养价值的影响评定. 南昌: 江西农业大学, 2012. | |

| 35 | Li X L, Zhang X Y, Tang Y G, et al. Effect of concentrate-forage ratio in diet on live weight gain of stall-fed goats. Acta Prataculturae Sinica, 2008(2): 85-91. |

| 李向林, 张新跃, 唐一国, 等. 日粮中精料和牧草比例对舍饲山羊增重的影响. 草业学报, 2008(2): 85-91. | |

| 36 | Colombatto D, Hervás G, Yang W Z, et al. Effects of enzyme supplementation of a total mixed ration on microbial fermentation in continuous culture, maintained at high and low pH. Journal of Animal Science, 2003, 81(10): 2617-2627. |

| 37 | Diao Q Y, Tu Y. Degradabilities of crude protien in feedstuffs for dairy cow in rumen. Journal of Dairy Science and Technology, 2005(2): 70-74. |

| 刁其玉, 屠焰. 奶牛常用饲料蛋白质在瘤胃的降解参数. 乳业科学与技术, 2005(2): 70-74. | |

| 38 | Jimmy H C, David K R, Richard A E, et al. The nutrition requirement of dairy cows. 7th edition. Meng Q X, translate. Beijing: China Agricultural University Press, 2002: 1-2. |

| Jimmy H C, David K R, Richard A E, et al. 奶牛营养需要. 第七版. 孟庆翔, 译. 北京: 中国农业大学出版社, 2002: 1-2. | |

| 39 | Feng Y L, Lu D X, Lu Z N, et al. Nutritional requirements and feed ingredients of dairy cows. Beijing: China Agriculture Press, 2007. |

| 冯仰廉, 卢德勋, 陆治年, 等. 奶牛营养需要和饲料成分. 北京: 中国农业出版社, 2007. |

| [1] | 陈德奎, 吴硕, 邹璇, 周玮, 陈晓阳, 张庆. 邻苯二酚对香椿叶青贮营养品质及抗氧化性的影响[J]. 草业学报, 2022, 31(3): 207-213. |

| [2] | 吴欣明, 方志红, 池惠武, 贾会丽, 刘建宁, 石永红, 王学敏. 30个青贮玉米在雁门关地区品种评比试验[J]. 草业学报, 2022, 31(1): 205-216. |

| [3] | 温媛媛, 张美琦, 刘桃桃, 沈宜钊, 高艳霞, 李秋凤, 曹玉凤, 李建国. 体外产气法评价生薯条加工副产品-稻草混贮与全株玉米青贮组合效应的研究[J]. 草业学报, 2021, 30(8): 154-163. |

| [4] | 杨冬梅, 李俊年, 陶双伦. 添加单宁酸对青贮葛藤有氧稳定性和霉菌毒素含量的影响[J]. 草业学报, 2021, 30(8): 164-170. |

| [5] | 郭香, 陈德奎, 陈娜, 李云, 陈晓阳, 张庆. 含水量和添加剂对黄梁木叶青贮发酵品质的影响[J]. 草业学报, 2021, 30(8): 199-205. |

| [6] | 邹诗雨, 陈思葵, 唐启源, 陈东, 陈元伟, 邓攀, 黄胥莱, 李付强. 青贮剂对再生稻头季全株青贮品质和体外瘤胃发酵特性的影响[J]. 草业学报, 2021, 30(7): 122-132. |

| [7] | 尹祥, 王咏琪, 李鑫琴, 田静, 王晓亚, 张建国. 不同水分吸附材料对象草青贮发酵品质及好氧稳定性的影响[J]. 草业学报, 2021, 30(7): 133-138. |

| [8] | 袁英良, 唐丹, 鲁英, 冉桂霞, 郭艳芹. 吉林地区麦后复种饲用油菜与燕麦混播效应研究[J]. 草业学报, 2021, 30(7): 167-178. |

| [9] | 张丹丹, 张元庆, 程景, 靳光, 李博, 王栋才, 徐芳, 孙锐锋. 不同粗饲料组合对晋南牛瘤胃体外发酵特性的研究[J]. 草业学报, 2021, 30(7): 93-100. |

| [10] | 黄丽琴, 李松桥, 袁振中, 唐晶, 闫景彩, 唐启源. 全株水稻与平菇菌糠共发酵料对浏阳黑山羊屠宰性能、肉品质和器官指数的影响[J]. 草业学报, 2021, 30(6): 133-140. |

| [11] | 祁鹤兴, 芦光新, 李宗仁, 徐成体, 德科加, 周孝娟, 王英成, 马桂花. 青海省青贮玉米链格孢叶枯病病原菌鉴定及其致病力分析[J]. 草业学报, 2021, 30(6): 94-105. |

| [12] | 谢展, 穆麟, 张志飞, 陈桂华, 刘洋, 高帅, 魏仲珊. 乳酸菌或有机酸盐与尿素复配添加对紫花苜蓿混合青贮的影响[J]. 草业学报, 2021, 30(5): 165-173. |

| [13] | 吕竑建, 郭香, 陈德奎, 陈晓阳, 张庆. 植物乳酸菌和贮藏温度对辣木叶青贮品质的影响[J]. 草业学报, 2021, 30(3): 121-128. |

| [14] | 张生伟, 王小平, 张展海, 马友记, 滚双宝, 杨巧丽, 高小莉, 张保军. 青贮杂交构树对杜湖杂交肉羊生长性能、血清生化指标和肉品质的影响[J]. 草业学报, 2021, 30(3): 89-99. |

| [15] | 袁洁, 马冉冉, 张文洁, 许能祥, 赵冉冉, 顾洪如, 丁成龙. 自然青贮多花黑麦草优良乳酸菌的筛选及对多花黑麦草青贮品质的影响[J]. 草业学报, 2021, 30(11): 132-143. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||